Environment

Environment Economic

Economic

Water is a basic human necessity. According to the World Economic Forum (WEF) Report on Global Risks 2017, water crisis is one of the top risks that plague the world today. Today 40% of global population is affected by water scarcity and this figure is projected to rise1. Rising urban population, coupled with poor planning and rising income levels, have placed an unprecedented pressure on urban infrastructure severely stressing available water reserves. As per 2030 Water Resources Group Report, projected water demand would exceed the existing sustainable water supply by 40%2. The world will not be able to strengthen the pillars of sustainable development that is - human development, liveable cities, food security and energy security, without improving the management of water resources and ensuring reliable access to water.

India echoes many of the global challenges like environmental degradation, water crisis, poverty, social inequalities, unemployment, and food crises. In addition to it, India is also being confronted with multitude of problems arising out of climate change like floods, droughts, sea water ingression in coastal areas etc. According to a 2030 Water Resources Group Report2, India would face 50% aggregate gap between projected demand and existing water supply in 2030 due to high growth in agricultural, municipal and domestic demand. The gap may further worsen due to risks posed by climate change. With around 55% of net sown area meeting its water requirements from rainwater3, the agri-sector is especially vulnerable to extreme weather phenomena like droughts and shifting rainfall patterns, brought about by climate change. On the other hand, India's water supply remains constrained owing to inefficient use of water, over exploitation of ground water reserves and variations in surface water availability.

For ITC, water forms a crucial input and has impacts in the entire value chain. Therefore, ITC has sought to engage actively with agencies like Alliance for Water Stewardship (AWS), World Business Council for Sustainable Development (WBCSD), World Resources Institute (WRI), International Water Management Institute (IWMI), etc., to share experiences and also improve the understanding of the complex social and technical issues related to water. While ITC has achieved a unique position by creating an overall positive water footprint through well-crafted strategies, efforts are now channelised to achieve water security for all stakeholders within defined catchment areas, for units located in highly water stressed areas. It is carrying out comprehensive studies through reputed agencies in assessing water use and implementing specific interventions which will help to improve water usage efficiencies and augment the supply for all stakeholders within the catchment areas. (Please refer to 'ITC Mission Sunehra Kal for Sustainable & Inclusive Growth' chapter of this Report for more information on ITC's interventions at watershed level).

Based on this evolving water scenario, ITC has mapped its challenges and the actions being taken.

1///www.un.org/en/sections/issues-depth/water

2Charting our Water Future, Report by 2030 Water Resources Group, 2009

3Prioritisation of Rainfed Areas in India, Planning Commission Report, February 2012

In 2016-17, ITC's total water intake was 31.29 million kilolitres (kl) a decrease of 7.43% over the previous year (33.80 million kl in 2015-16). This performance is primarily attributable to the on-going initiatives undertaken towards water conservation across ITC Units.

Of the 31.29 million kl of total water intake, 78.79% of water resources was sourced from surface water, 18.71% from ground water sources and only 2.50% from municipal and other water sources.

In order to continually improve performance in resource conservation, all ITC Units have developed systems to monitor the specific water intake (total water intake per unit of product/service). Considering the fact that three Units of Paperboards and Specialty Papers Division (PSPD) together accounted for around 88.8% of total water intake of ITC, efforts have been focused on the performance of these Units (as given in the following section) under this Business.

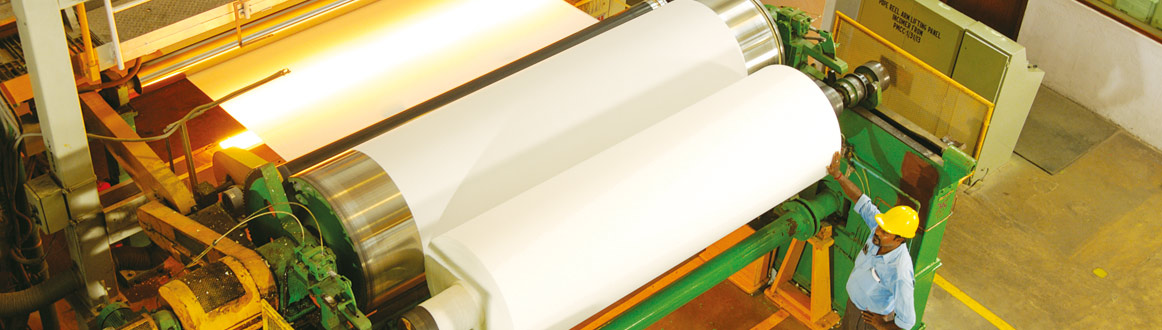

India's largest integrated pulp and paperboards mill accounted for 75.58% of the total water intake by ITC. For the year 2016-17, Bhadrachalam Unit set a target of 39.4 kl per tonne of product for its specific water intake. The Unit achieved specific water intake of 38.99 kl/tonne, well within the target set and a reduction of 5.9% over the previous year's 41.44 kl/tonne. This was primarily due to following water conservation measures undertaken by the Unit:

Case Study: Reduction of specific water intake in PSPD, Bhadrachalam

PSPD Bhadrachalam is India's largest integrated pulping and paperboard manufacturing unit. Since Pulp & Paper Industry is highly water intensive, significant investments have been made in the last two decades to address this aspect.

Technological interventions and intensive in-house efforts have resulted in reduction in overall specific water consumption by 5.9%.

Tribeni Unit manufactures specialty paper, which uses a water intensive process. For the year 2016-17, Tribeni Unit had set a target of 60 kl/tonne for its specific water intake, as per the norms issued by regulatory agencies. In 2016-17, the Unit achieved 58.58 kl/tonne which is a significant 28.84% reduction over 2015-16.

Case Study: Reduction of specific water intake in PSPD, Tribeni

The Unit has implemented the following measures on the basis of 3R (Reduce, Reuse and Recycle) principle to achieve significant reduction in specific water intake.

Reduce:

Reuse:

Recycle:

Water conservation measures undertaken at paper mill and utilities areas led to the reduction in specific water intake from 11.19 kl/tonne in 2015-16 to 10.55 kl/tonne in 2016-17. The following measures undertaken by the Unit enabled it to meet its 2016-17 specific water intake target of 11 kl/tonne.

All ITC Units met the regulatory requirements of discharge quality and quantity in 2016-17. The two Paperboards and Specialty Papers Units at Bhadrachalam and Tribeni accounted for 98.58% of total treated waste water discharged outside Unit premises in ITC, out of which overall 60.67% was utilised for irrigation purpose. Therefore, specific focus has been accorded to the performance of these 2 Units in terms of treated effluent discharge volume as well as quality.

Both for Bhadrachalam Unit (from 2011-12 onwards) and Tribeni Unit (from 2014-15 onwards), there is a continually decreasing trend of specific treated effluent discharged.

The specific treated effluent discharged for PSPD Bhadrachalam is 38.3 kl/Bone Dry Metric Tonne (BDMT) which is superior compared to benchmark figure of 47 kl/BDMT of European pulp and paper industry4.

Since 2010-11, the wastepaper-based pulp and paper mill at Kovai has not discharged any treated effluent outside its premises. In 2016-17, the specific treated effluent discharged (within the unit for irrigation) is 5.9 kl/tonne, which is significantly lower than the proposed NPC standard of 15 kl/tonne.

The quality of the treated effluent from Paperboards and Specialty Papers Units has been maintained at levels superior to the stipulated norms by the State Pollution Control Board (SPCB).

4Technical EIA Guidance Manual for Pulp and Paper Industries- IL&FS Environment

The level of adsorbable organic halides (AOX) generated during the bleaching process is another critical parameter applicable only to ITC's Bhadrachalam Unit. These compounds are formed as a result of reaction between residual lignin from wood fibres and chlorine compounds used for bleaching.

Depicted below is the specific AOX level for Bhadrachalam Unit for the year 2016-17 showing that the level is well below the norm stipulated by Ministry of Environment, Forest and Climate Change (MoEFCC) as well as national and international benchmarks.

In line with the Board approved Policies on Life-cycle Sustainability and Responsible Sourcing, in 2014-15, ITC had initiated the process of accounting for water intake of supply chain members. In 2016-17, the total water intake for ATC Limited (an associate Company), and two exclusive Third Party Manufacturers for the Cigarettes Business, together was 26,093 kl. In the coming years ITC intends to include its supply chain members within the reporting boundary.

The Company's continued interventions in rainwater harvesting both in the Company premises and socially relevant watershed areas have enlarged its water positive footprint. Details on these interventions are available in the 'ITC Mission Sunehra Kal for Sustainable & Inclusive Growth' section of this Report.

As on March 31, 2017, ITC's Integrated Watershed Development Projects, covering 7,76,316 acres of land, support the Water Positive status of the Company for the 15th year in a row. Due to focused efforts on reducing net water consumption through various water conservation initiatives across the Businesses and increasing the total rainwater harvesting potential created within the Units and through watershed development initiatives, the rainwater harvesting potential created is now over three times the net water consumption by its operations.

From 2008-09, a factor based on sample measurement is being used to account for reduction in storage capacity due to siltation. This applies to all RWH surface storage bodies created inside and outside the Company premises.

While continuing its integrated watershed management programme, ITC will be guided by the principles of water stewardship to ensure water security for all stakeholders across all its operating Units.