The challenges related to environment and ecosystems especially due to climate change are complex, long-term and inter-related, especially in terms of its impact on water and availability of other natural resources. This in turn has wide-ranging implications on ITC and its stakeholders. ITC accordingly has identified several physical and regulatory risks that can impact the long-term sustainability of the organisation:-

- In India, about 75% of its population and around 50% of its workforce is dependent on agriculture and related activities for livelihoods. Since over two-thirds of agricultural output is generated through rain-fed agriculture, any change in precipitation patterns owing to climate change would significantly disrupt yields.

- Retreating glaciers will also adversely impact water availability in snow-fed rivers, which are a lifeline to a significant portion of the country's population. Rising sea levels on the other hand will increase the risk of contaminating coastal groundwater supplies, thereby further aggravating the situation.

- Resultant disruption in crop yields could lead to increased competition for agricultural commodities.

- Extreme weather events like hurricanes and typhoons are an anticipated outcome of climate change. These may pose a major threat to ITC properties in coastal areas and may disrupt operations. These extreme weather events can also disrupt rail and road traffic links,further affecting supply of essential raw materials and finished goods.

- Increased temperatures would increase air conditioning costs and also impact agricultural productivity.

- Energy security is expected to be one of the biggest developmental challenges with around 400 million people lacking reliable access to energy in India. Climate change impacts will assume increasing importance in the context of continued usage of fossil fuels and development of viable sustainable alternatives and achieving highest levels of energy efficiency will be of paramount importance.

- India's commitment to the United Nations Framework Convention on Climate Change, to reduce its GHG emissions per unit of GDP by 20-25% by 2020 over 2005 levels (as part of the Nationally Appropriate Mitigation Action plan) is also in alignment with its National Action Plan on Climate Change. This could lead to a carbon tax or additional requirements under the Perform, Achieve, Trade (PAT) and Renewable Energy Certificates (REC) schemes in order to incentivise low carbon energy usage, which could have an impact on our Paperboards and Specialty Papers Business.

- Rapid and unplanned urbanisation is putting increasing pressure on basic civic infrastructure and issues such as municipal waste disposal are assuming critical importance. Given our significant presence in the FMCG as well as Packaging Business segments, ITC also cognises for these concerns. The Company is progressively implementing appropriate programmes in partnership with Civil Society Organisations to address the twin issues of waste management and creation of sustainable livelihoods for people engaged in the informal rag picking business.

Management Approach

At an organisational level, the Company has adopted the following approach in its relentless efforts to continuously improve environmental performance:-

- Ensuring the sustainability of agriculture through integrated watershed development and soil and moisture conservation projects whilst creating sustainable livelihoods for large numbers of marginal farmers.

- Evaluating agricultural productivity/adaptation issues related to climate change and providing support to farmers through extension services which includes information on better agricultural practices, market access, etc.

- Maximising water usage efficiencies and augmenting rainwater harvesting.

- Reinforcing the protection of our assets in coastal areas in anticipation of increased severity of storms and cyclones.

- Developing appropriate contingency and insurance plans for uninterrupted production and delivery, in situations of extreme weather events that may disrupt road and rail traffic.

- Moving beyond statutory compliance with respect to emissions, effluents and wastes.

- Incorporating "Green Building"/"Green Factory" features into existing and upcoming establishments.

- Adopting a low carbon growth path by reducing specific energy consumption, increasing the use of energy from renewable sources, reducing specific GHG emissions and enhancing carbon sequestration.

- Contributing towards waste management through minimisation of its own waste generation, maximising waste reuse & recycling and using post-consumer waste as raw material.

ITC Businesses have internalised environmental best practices on the basis of which, it strives to maximise the efficiencies of natural resource usage across its operations. In addition, ITC also constantly endeavours to create a positive environmental footprint. Large-scale Social and Farm Forestry, Integrated Watershed Development, Sustainable Agriculture Practices and logistic network optimisation of our FMCG products, etc. are a few examples of extensive initiatives in this direction.

Board approved Policies such as those on Environment, Health and Safety, Life Cycle Sustainability of Products and Services and Responsible Sourcing, provide the necessary direction to address the direct impacts of the Company's own operations as well as progressively extend the efforts along the supply chain. (please refer to Policies available at www.itcportal.com)

It is the overall responsibility of the Divisional/Strategic Business Unit (SBU) Chief Executives, through the members of the respective Management Committees, General Managers and Unit Heads, to ensure implementation of relevant policies and standards on environmental performance. This also includes institution of various committees and designating specific responsibilities.

ITC's Corporate Environment, Health & Safety (EHS) Department is responsible for reviewing and updating Corporate Standards, verifying compliance, providing guidance and support as required. Compliance is regularly monitored and evaluated by the Sustainability Compliance Review Committee (SCRC) of the Corporate Management Committee (CMC).

The Road Ahead

At present, some of the businesses have completed necessary internal assessments so as to set targets and record progress on key performance indicators. The implementation of an organisation-wide integrated sustainability data management system provides the platform to benchmark performance internally among business units, as well as monitor data of each business on resource utilisation and environmental impact vis-a-vis production. Studies are being carried out so that business-wise quantified targets can be progressively defined for prioritised material environmental aspects.Systems for performance review against targets are also being put in place. Going forward, ITC will also undertake life cycle assessment studies of more of its products and services for identifying opportunities to continuously improve environmental impacts across the value chain.

Management Approach

Economic progress and long-term business sustainability are today threatened by the challenge of natural resource depletion and its impacts on long term energy security. This is manifest in the consistent and sharp increase in electricity and fuel prices over the years.

ITC has responded to the evolving energy scenario in the country by aligning its corporate strategy so as to ensure:

1. Identification and evaluation of energy security risks given ITC's future expansion plans, evolving regulatory frameworks, techno-commercial feasibility and socio-political aspects.

2. Phased implementation of energy conservation initiatives and renewable energy generation projects.

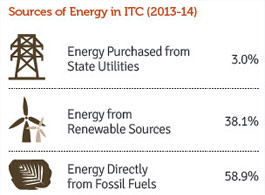

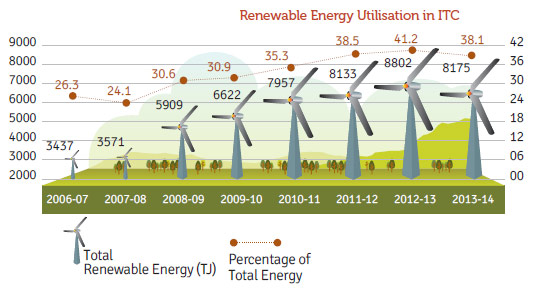

In 2013-14, 38.1% of the total energy consumption of ITC was met from renewable energy sources. ITC intends to achieve a 50% renewable energy share by 2020 in a progressive manner. A detailed study was carried out during 2013-14 to understand the issues related to the achievement of this target, taking into account various businesses as well as unit-specific aspects like existing energy portfolio and energy conservation & renewable energy projects, future expansion plans, etc. Evolving regulatory frameworks in each state were also taken into account, for instance Perform Achieve and Trade (PAT) mechanism, Renewable Energy Purchase Obligation, etc. Since the Paperboards and Specialty Papers Business accounts for 90% of the Company's energy consumption, special attention was paid to its unique requirements.

Our Performance

ENERGY CONSUMPTION WITHIN THE ORGANISATION

In 2013-14, ITC Units consumed 21,433 Terra Joules (TJ) of energy. Despite significant growth in almost all businesses (7.8% growth in production volumes at Paperboards and Specialty Papers Business itself), there has been a marginal increase of 0.4% in the total energy consumption as compared to the previous year (21,347 TJ in 2012-13). This has been achieved through better capacity utilisation and concerted efforts on energy conservation implemented across several ITC Units.

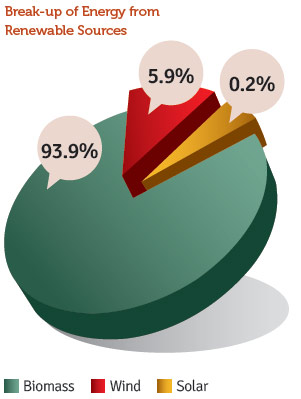

Renewable energy to the extent of 8,175 TJ in ITC was derived from the following sources:-

- Black liquor waste from pulping process and waste wood biomass from chipping operations in the Bhadrachalam Unit and locally sourced chip/sawdust and deoiled bran in the Kovai Unit of the Paperboards and Specialty Papers Business

- Wind Energy farms for Packaging & Printing, Cigarettes, Hotels, Paperboards & Specialty Papers and Leaf Tobacco Businesses

- Solar thermal systems in several Units

In 2013-14, the total energy contribution from renewable sources, decreased by 7.1% over the previous year (8,802 TJ in 2012-13).

Primary contributors to this decline in renewable energy generation were:-

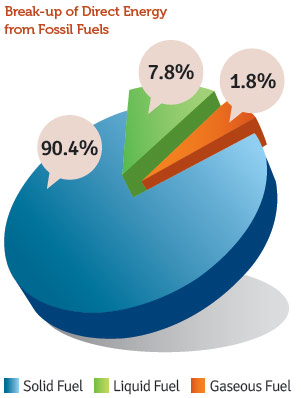

- The Paperboards Unit at Bhadrachalam confronted the challenge of reduced availability of domestic wood, which led to a reduction in the production of virgin pulp and greater dependence on imported pulp. This in turn resulted in reduced generation of black liquor which was compensated by higher coal production.

- Reduced consumption of chip/saw dust and deoiled bran due to availability issues at the Paperboards Unit in Kovai.

Substantial improvements in specific energy performance were achieved at many of the Units through a focused approach on energy conservation through rigorous third party audits and implementation of the recommendations coupled with better capacity utilisation. As a result of implementation of energy conservation measures, a saving of 81.03 TJ in direct energy consumption and of 45.99 TJ in indirect energy consumption has been achieved in 2013-14.

The LEED® Platinum rating has been accorded to all of ITC's luxury hotels, making it the greenest luxury hotel chain in the world. This, in effect, implies a significant reduction in specific energy consumption with respect to conventionally designed hotels. ITC hotels are not only energy efficient by design but also conserve fossil fuels by maximising use of wind energy. Several of ITC's hotels are sourcing 100% of their electrical energy requirements from wind farms. In order to continually reduce our energy footprint, green features are also being incorporated in all existing hotels, manufacturing Units, warehouses and office complexes apart from all new construction.

| Businesses | Energy consumption (in TJ) | % Contribution to ITC Total |

| Paperboards and Specialty Papers | 19,264 | 89.9% |

| Hotels | 612 | 2.9% |

| Leaf Tobacco | 421 | 2.0% |

| Cigarettes | 369 | 1.7% |

| Foods & Personal Care Products | 375 | 1.7% |

| Packaging and Printing | 293 | 1.4% |

| Others* | 99 | 0.4% |

* Others include Agri Business, ITC Infotech, ITC Life Sciences & Technology Centre and large offices

Provided below is a snapshot of the Units where specific energy consumption has improved significantly in 2013-14, over the previous year:

| Name of Unit | Specific Energy Consumption in | Unit of Measurement | Percentage Reduction | Remarks | |

| 2012-13 | 2013-14 | ||||

| Paperboards and Specialty Papers Unit at Kovai | 16.63 | 13.79 | GJ/t | 17.1 | Improved capacity utilisation and implementation of energy conservation measures |

| Printing and Packaging Unit at Haridwar | 5.42 | 4.74 | GJ/t | 12.5 | Improved capacity utilisation and implementation of energy conservation measures |

| Hotel ITC Maurya | 0.79 | 0.70 | GJ/Number of Guest Room Nights | 11.4 | Implementation of energy conservation measures |

| Cigarette Unit at Munger | 5.37 | 4.81 | GJ/MNC eq.* | 10.4 | Improved grid availability and implementation of energy conservation measures |

| Paperboards and Specialty Papers Unit at Bhadrachalam | 33.77 | 31.25 | GJ/t | 7.5 | Reduction in pulping volumes and implementation of energy conservation measures |

Figures are rounded off to nearest decimal

* MNC eq - Million Number of Cigarettes equivalent

However, specific energy consumption has increased in the Units mentioned in the table below during 2013-14 in comparison to the previous year. Though these Units contribute only 1.2% to the overall ITC energy consumption figures, measures are being initiated to reverse the trend.

For calculating energy consumption within the organisation, ITC has followed the World Resources Institute (WRI) and World Business Council for Sustainable Development (WBCSD) 'GHG Corporate Accounting and Reporting Standard'. In order to ensure adoption of uniform methodologies across the organisation, Standard Operating Procedures have been laid down, to facilitate quality control in terms of monitoring, recording and finally collation, using ITC's Integrated Sustainability Data Management System (ISDMS). Energy factors (Net Calorific Values) for solid fuels are taken from the actual fuel-test reports while for liquid and gaseous fuels, default factors from the IPCC Guideline for National Green House Gas Inventories (2006) have been taken into consideration.

| Name of Unit | Specific Energy Consumption in | Unit of Measurement | Percentage Reduction | Remarks | |

| 2012-13 | 2013-14 | ||||

| Cigarettes manufacturing Unit at Kolkata | 1.58 | 1.95 | GJ/MNC eq | 23.4 | Due to ongoing project activities, parallel production facilities being maintained. This was a temporary arrangement and with commissioning of new facility in Jan 2014. |

| Personal Care Products (Soap) Unit at Manpura | 0.83 | 1.03 | GJ/t | 24.1 | Change in the product mix |

| Foods (Biscuit) Unit at Haridwar | 3.08 | 3.66 | GJ/t | 18.8 | Addition of new product variants |

| Packaging and Printing Unit at Tiruvottiyur | 4.30 | 5.08 | GJ/t | 18.1 | Change in the product mix, new product and 'label' and increase in flexibles |

Figures are rounded off to nearest decimal

ENERGY CONSUMPTION OUTSIDE OF THE ORGANISATION

During 2013-14, ITC has expanded the boundary of energy accounting, both upstream and downstream. Accordingly, 1,641 TJ of energy consumed outside of the organisation has been accounted for in 2013-14 as part of inbound transportation of raw materials, outbound transportation of products and wastes, employee commuting, local road travel by Hotels business guests, Third Party Manufacturing (TPM) units catering to the notebooks segment of Education and Stationery Products Business, and ATC Limited, an associated company. For computation methodology, please refer to Annexure - GHG Inventory: Quantification Methodologies. The boundary of accounting will be progressively expanded in the years to come, based on our ability to overcome challenges with regard to data quality.

The Road Ahead

Based on a holistic feasibility analysis and the fact that majority of the Company's energy consumption in the entire value chain of products is attributable to manufacturing operations, ITC's businesses will continue to accord high priority to energy efficiency projects within a Unit's premises. ITC recognises that availability of biomass for fuel will face increasing competition and while solar and wind energy can contribute towards meeting electrical energy requirements, finding alternatives to fossil fuel for meeting its thermal energy requirements will be more challenging. Accordingly specific focus will be accorded to energy conservation and efforts will be made to drive the same in a strategic manner.

Greenhouse Gases

Management Approach

ITC firmly believes that the future competitiveness of organisations will depend on their ability to adopt effective strategies for a low carbon growth path. ITC has responded to the challenges emerging from the threat of climate change by aligning its corporate strategy with the National Action Plan on Climate Change (NAPCC). This has already been detailed in the 'Disclosure on Management Approach' section.

Our Performance

ITC has computed its greenhouse gas (GHG) inventory, including GHG emissions, biogenic carbon dioxide (CO2) emissions and GHG removals, in accordance with ISO 14064:2006, which is the latest international standard specifying principles and requirements at the organisation level for quantification and reporting of GHG emissions and removals. The 2013-14 inventory has been verified by KPMG at the "Reasonable Assurance" level. To set organisational boundaries for consolidated GHG emissions, ITC has utilised the operational control approach for the various entities covered under the Report. Based on applicability, ITC has accounted for the following gases in its GHG inventory: Carbon Dioxide (CO2), Methane (CH4), Nitrous Oxide (N2O), Hydrofluorocarbons (HFCs), Perfluorocarbons (PFCs) and Sulphur Hexafluoride (SF6).

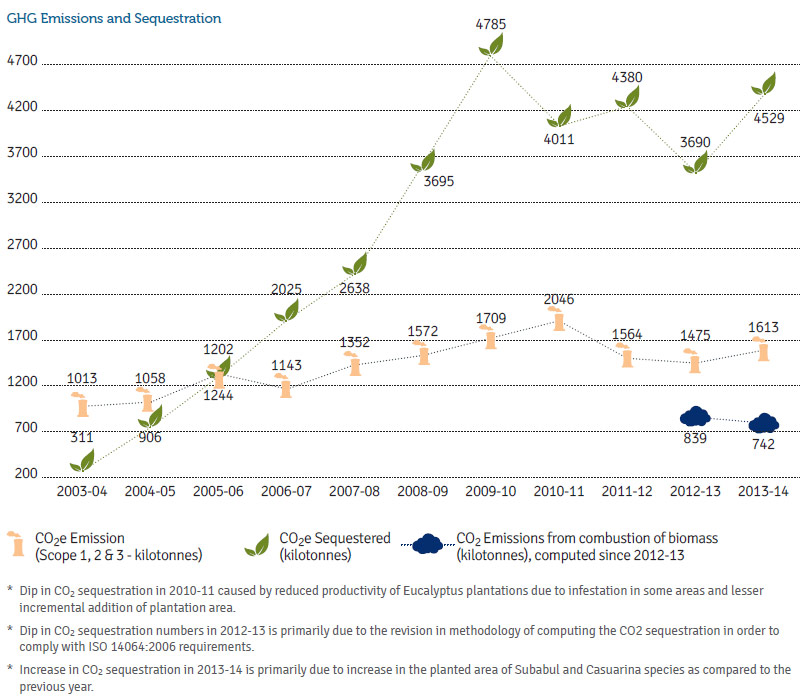

In 2013-14, ITC's total GHG emissions (Scope 1, 2 &3) were 16,12,914 tonnes of CO2-equivalent (14,74,558 tonnes in 2012-13) and CO2 emissions from combustion of biomass was 7,42,220 tonnes (8,38,969 tonnes in 2012-13). The increase in total GHG emissions with respect to 2012-13 is primarily attributable to the following:

In 2013-14, ITC's total GHG emissions (Scope 1, 2 &3) were 16,12,914 tonnes of CO2-equivalent (14,74,558 tonnes in 2012-13) and CO2 emissions from combustion of biomass was 7,42,220 tonnes (8,38,969 tonnes in 2012-13). The increase in total GHG emissions with respect to 2012-13 is primarily attributable to the following:

- Increase in Scope 1 emissions as a result of increased fossil fuel consumption due to the reduced availability of bio-mass in the Paperboards and Specialty Papers Business, as well as the inclusion of two new Units, the Mysore Unit of ITC's Leaf Tobacco Business and ITC Grand Chola of ITC's Hotels Business, within the reporting boundary (please refer to Energy section in page 90 for further details)

- Increase in Scope 3 emissions owing to inclusion of emissions from transportation of materials by ITC's Agri Business Division and the Mysore Unit of the Leaf Tobacco Business as well as increased emissions from transportation of products and raw materials by ITC's Paperboards and Specialty Papers Business.

G4-21

ITC's GHG inventory for the year 2013-14 is as follows:

| Direct GHG Emissions (Scope 1) | 12,34,128 tonnes |

| CO2 Emissions from combustion of biomass | 7,42,220 tonnes |

| Energy Indirect GHG Emissions (Scope 2) | 1,76,649 tonnes |

| Other Indirect GHG Emissions (Scope 3) | 2,02,137 tonnes |

| GHG Removals | 45,29,311 tonnes |

ITC's Social and Farm Forestry Initiatives have added close to 21,000 hectares of plantations during 2013-14. Total plantations as on March 31, 2014 stand at over 1,63,000 hectares. The Social and Farm Forestry Initiatives have helped sequester 45,29,311 tonnes of CO2 in this year, thus consolidating ITC's status as a 'Carbon Positive Company' for the 9th year in a row.

From 2013-14 onwards, ITC has started monitoring the GHG intensity of its operations, in terms of the Scope 1 and Scope 2 emissions:-

Specific GHG emissions of Paperboards and Specialty Papers Business Units, which together accounted for around 82% of total GHG emissions (Scope 1 and Scope 2) in ITC, are given in the table below.

Paperboards and Specialty Papers Business

| Name of Unit | Specific GHG Emissions (tCO2e/ tonne of production) |

| Bhadrachalam | 1.71 |

| Bollaram | 0.10 |

| Kovai | 1.08 |

| Tribeni | 4.80* |

* This Unit specialises in low GSM products and laminates which are energy intensive, and uses fossil fuel based energy.

The specific GHG emissions of ITC's other businesses, which contributed to about 16% of the total GHG emissions (Scope 1 and Scope 2), are given below.

| Business | Specific GHG Emissions | Unit for Specific GHG Emissions |

| Cigarettes | 0.593 | tCO2e/ MNC eq |

| Foods | 0.518 | tCO2e/ tonne |

| Packaging and Printing | 0.504 | tCO2e/ tonne |

| Leaf Tobacco | 0.425 | tCO2e/ tonne |

| Hotels | 0.087 | tCO2e/ Number of Guest Room Nights |

ITC's accounting of Scope 1, 2 & 3 GHG emissions is based on the 'GHG Protocol Corporate Accounting and Reporting Standard' and the 'GHG Protocol Corporate Value Chain (Scope 3) Accounting and Reporting Standard' issued by the World Resources Institute (WRI) and the World Business Council for Sustainable Development (WBCSD). The standards, methodologies, tools and assumptions used for quantification of the GHG emissions and removals by various sources, have been explained at length in Annexure – GHG Inventory: Quantification Methodologies.

ITC's efforts in energy reduction across its various Units and the optimisation of distribution logistics of finished goods for its FMCG Businesses have helped control GHG emissions in 2013-14.

In 2013-14, 20,909 tonnes of GHG emissions (scope 1 & 2) were avoided by the implementation of energy conservation measures.

Specific Scope 3 emissions due to transportation of FMCG products (Cigarettes, Personal Care and Foods) in 2013-14 have decreased by 8.1% (tonnes of CO2e emission/tonne of product transported) as compared to the previous year for the same product categories. This has been achieved by improvement in vehicle utilisation capacity across the supply chain and extensive network de-layering in order to increase direct shipments to destination warehouses, thereby avoiding intermediate movements.

The Road Ahead

ITC intends to progressively expand the boundary for monitoring and reporting of Scope 3 GHG emissions, beyond the existing coverage of significant Third Party Manufacturers (TPMs), upstream and downstream transportation of materials and employee commuting. Our focus will be to continuously reduce Specific GHG emissions in manufacturing operations as well as transportation of materials.

In order to spearhead its carbon positive growth path, ITC plans to set realistic and tangible targets of reduction in specific Scope 1 and 2 emissions based on historical performance as well as future plans. It is expected that the process of target setting for each Business and individual Units will be completed during 2014-15.

OTHER SIGNIFICANT AIR EMISSIONS

Management Approach

Uncontrolled air pollution in terms of emissions of SOx, NOx, Particulate Matter etc. may have adverse impacts on vegetation, health of human beings and animals, biodiversity as well as crop yields. Cognising for the adverse impacts of air pollutants on the ecosystem and the critical need towards mitigating them, ITC has continued to invest in reducing air emission levels through adoption of cleaner technologies/fuels, monitoring of combustion efficiencies and investment in state-of-the-art pollution control equipment, such as plasma filters and electrostatic precipitators.

Our Performance

All our Units monitor significant air emission parameters, such as Particulate Matter (PM), Nitrogen Oxides (NOX) and Sulphur Dioxide (SO2) on a regular basis to ensure compliance with internal norms that are more stringent than regulatory requirements.

All our Units monitor significant air emission parameters, such as Particulate Matter (PM), Nitrogen Oxides (NOX) and Sulphur Dioxide (SO2) on a regular basis to ensure compliance with internal norms that are more stringent than regulatory requirements.

In 2013-14, total significant air emissions included 781 tonnes of PM, 776 tonnes of NOX and 883 tonnes of SO2 emission (in 2012-13, PM: 690, NOx: 649 and SO2: 790 tonnes). The increase in the total emissions over last year was due to the increased utilisation of fossil fuels in ITC, as a result of reduced availability of bio-mass.

In 2013-14, PM emission from the Bhadrachalam Unit was 0.972 kg per BDMT (Bone-Dry Metric Tonne) of production, way below the average emission of 3.8 kg per BDMT by large scale Indian mills as per the Report by the Centre for Science & Environment (Source: 'All About Paper – The life cycle of Indian Pulp and Paper Industry', Green Rating project, 2004).

In 2013-14, the specific NOx emission in the Unit at Bhadrachalam continued to be lower than the standards stipulated in European countries, as illustrated below:

| Bhadrachalam | NOx (kg/tonne) | ||||||

| 2007-08 | 2008-09 | 2009-10 | 2010-11 | 2011-12 | 2012-13 | 2013-14 | |

| 0.43 | 0.69 | 0.60 | 0.58 | 0.46 | 0.35 | 0.33 | |

| Standards | |||||||

| Sweden | 1.2-2.4 | ||||||

| EU | 1.0-1.8 | ||||||

| EU-BAT* | 1.0-1.5 | ||||||

| Reported Values | |||||||

| CEPI** | 0.85 | ||||||

The Bhadrachalam Unit is also progressing towards achieving international standards on specific SO2 emission levels, as given below:

| Bhadrachalam | SO2 (kg/tonne) | ||||||

| 2007-08 | 2008-09 | 2009-10 | 2010-11 | 2011-12 | 2012-13 | 2013-14 | |

| 0.50 | 0.84 | 0.79 | 0.74 | 0.61 | 0.53 | 0.51 | |

| Standards | |||||||

| Sweden | 0.5-1.4 | ||||||

| EU | 0.1-0.5 | ||||||

| EU-BAT* | 0.2-0.4 | ||||||

| Reported Values | |||||||

| CEPI** | 0.24 | ||||||

Sources - 1. Comprehensive Industry Document for Large-Scale Pulp & Paper Mills, study done by CPPRI, published by CPCB, 2007 *EU-BAT: EU Norm Best Available technology

2. ** CEPI – Confederation of European Paper Industries, Sustainability Report 2011

In addition to the above parameters, our Paperboards Unit at Bhadrachalam also monitors Hydrogen Sulphide, the average measured value of which for the year 2013-14 was 3.72 mg/Nm3, which was much lower than the regulatory norm of 10mg/Nm3.

Ozone Depleting Substances: In accordance with the Government of India's Ozone Depleting Substances (ODS) Rules, 2000, ITC has developed and implemented an ODS phase out plan. The main features of the plan include procurement of new equipments which are free of Chlorofluorocarbons (CFC), Halons and Methyl Chloroform (MCF); monitoring and reducing consumption of ODS; replacement of all the existing equipment using ODS well before the stipulated phase-out period and recover all the ODS from the equipment being replaced for recycling or safe disposal.

In 2013-14, the total consumption of ODS by all our Units was 79.1 kg of CFC-11 equivalent.

Responsible Management Of Chemicals, Oils and Fuels

All our Units manage chemicals, oils and fuels as per defined ITC norms, which take into account all statutory requirements and international best practices. These norms are taken into consideration right from the design stage and include measures for leakage/spillage prevention, provisions for containment, impervious flooring, leak detection system as well as all requirements as per Material Safety Data Sheets (MSDS) for hazardous chemicals. To avoid any incidence of uncontrolled spills or leakage, ITC has instituted safe work practices on handling and storage, procedures for leak detection & spill control and preventive maintenance. The effectiveness of these measures is checked on a regular basis.

All our Units manage chemicals, oils and fuels as per defined ITC norms, which take into account all statutory requirements and international best practices. These norms are taken into consideration right from the design stage and include measures for leakage/spillage prevention, provisions for containment, impervious flooring, leak detection system as well as all requirements as per Material Safety Data Sheets (MSDS) for hazardous chemicals. To avoid any incidence of uncontrolled spills or leakage, ITC has instituted safe work practices on handling and storage, procedures for leak detection & spill control and preventive maintenance. The effectiveness of these measures is checked on a regular basis.

We also continuously evaluate the feasibility of substituting hazardous chemicals with less or non-hazardous materials. In 2013-14, there was no significant spillage of any chemical, oil, fuel or hazardous waste in any of our Units.

The Road Ahead

All Units of ITC would continue to make concerted efforts in reducing specific emission levels. Significant reduction in specific emission levels will be achieved primarily through use of cleaner fuels, improvement in energy conservation and increased utilisation of renewable energy sources. The details are given in the Disclosure on Management Approach – Environment Section.

Management Approach

The availability of water continues to be a serious concern across the world. This problem will be further aggravated in India in the coming years, leading to a difficult and turbulent future arising out of severe water stress, as highlighted by the 2014 Inter-governmental Panel on Climate Change Report. The issue of water availability assumes critical significance in light of the fact that agriculture in India, which provides employment to over 50% of the workforce, is largely rain fed, with around 55% of net sown area meeting its water requirements from rainwater alone. Given the social and historical context of farming in India and the absence of adequate infrastructural support, any significant disruption in rainfall patterns will have considerable adverse impacts on agricultural yields. Such an untenable situation may even threaten the very fabric of social stability. Water availability therefore becomes especially critical for a Company like ITC, as most of its businesses depend significantly on agri-inputs.

Increased water scarcity may also impact ITC's Paperboards and Specialty Papers Business which is relatively more water intensive in its operations. With continuous decline in ground water and uneven supply of surface water, it may become even more challenging for businesses to meet their requirements.

Another issue that is assuming alarming proportions is the fact that disruptions in rainfall patterns will also impact water quality. Increased ground water mining is exacerbating an issue that has already assumed critical dimensions due to contamination as well as inadequate recharge. Such poor quality water requires additional treatment and additional costs before it can become usable. Risk of localised contamination like arsenic, fluoride, etc., which is already prevalent in some of the states where ITC operates, is also expected to increase. Such contamination can lead to severe health hazards and thus can have significant impacts.

These challenges may bring about additional regulatory limits on water withdrawal. These are already being enforced in some of the States where ITC operates and may affect operations due to a decrease in water availability.

Recognising the daunting challenges arising out of water-stress, ITC has adopted the following strategies that focus on the replenishment as well as conservation of this precious natural resource.

1. ASSESSMENT OF WATER STRESS AT ITC UNITS

ITC has undertaken the evaluation of water availability/ stress through stakeholder engagements and on the basis of data available with Government agencies. ITC is also engaged with World Business Council for Sustainable Development (WBCSD) in developing the 'India Water Tool' which will further help in the assessment of water related risks at the site-level.

2. WATER CONSERVATION

Conducting water audits, benchmarking and implementation of best practices to achieve the lowest possible specific freshwater intake (water per unit of product/service).

3. ZERO EFFLUENT DISCHARGE

Treating effluent so as to ensure that discharge quality is better than statutory requirements and progressing towards recycling/ reusing of all treated effluent.

4. RAIN WATER HARVESTING

Enhancing our water positive footprint through rainwater harvesting, both within our own Units and across different watershed areas.

5. WATER STEWARDSHIP

Work has been initiated on a pilot basis at one of our Units to work towards meeting the water security needs of all stakeholders at the local watershed level. This has been undertaken based on the principles of the Alliance for Water Stewardship (AWS) Standard. Based on the learning and outcomes, this will be extended across other business units as well.

Our Performance

Water Conservation

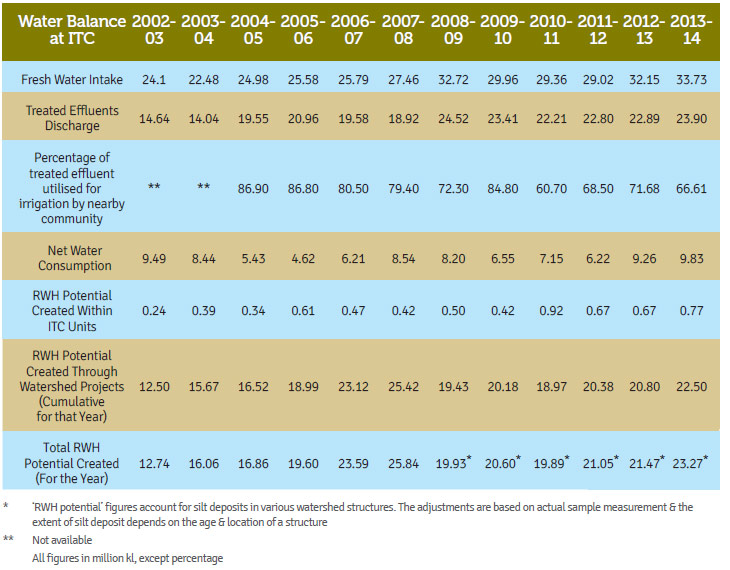

In 2013-14, ITC Units withdrew 33.73 million kilolitres (kl) of freshwater, an increment of 4.9% over the previous year (32.15 million kl in 2012-13). The increase in total fresh water intake can be attributed to the increased production of 7.8% by the Paperboards and Specialty Papers Business (accounting for around 92% of the total fresh water withdrawal by ITC), and inclusion of both the Mysore Unit of the Company's Leaf Threshing Business and ITC Grand Chola Chennai, of the Hotels Business into the reporting boundary. Focused efforts of all Units to reduce intake by conducting water audits, benchmarking and adopting leading practices facilitated the reduction of specific water intake as illustrated in the following sections.

In 2013-14, ITC Units withdrew 33.73 million kilolitres (kl) of freshwater, an increment of 4.9% over the previous year (32.15 million kl in 2012-13). The increase in total fresh water intake can be attributed to the increased production of 7.8% by the Paperboards and Specialty Papers Business (accounting for around 92% of the total fresh water withdrawal by ITC), and inclusion of both the Mysore Unit of the Company's Leaf Threshing Business and ITC Grand Chola Chennai, of the Hotels Business into the reporting boundary. Focused efforts of all Units to reduce intake by conducting water audits, benchmarking and adopting leading practices facilitated the reduction of specific water intake as illustrated in the following sections.

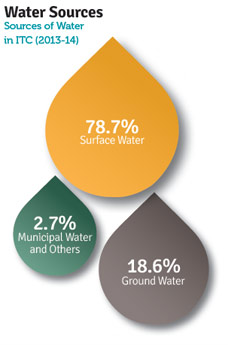

Of the 33.73 million kl of fresh water withdrawn, 78.7% of water resources were sourced from rivers, 18.6% from ground water sources and only 2.7% from municipal and other water sources.

This year, the Paperboards & Specialty Papers mills at Bhadrachalam, Kovai & Tribeni together accounted for 92.4% of the total fresh water withdrawal by ITC.

Paperboards Unit at Bhadrachalam

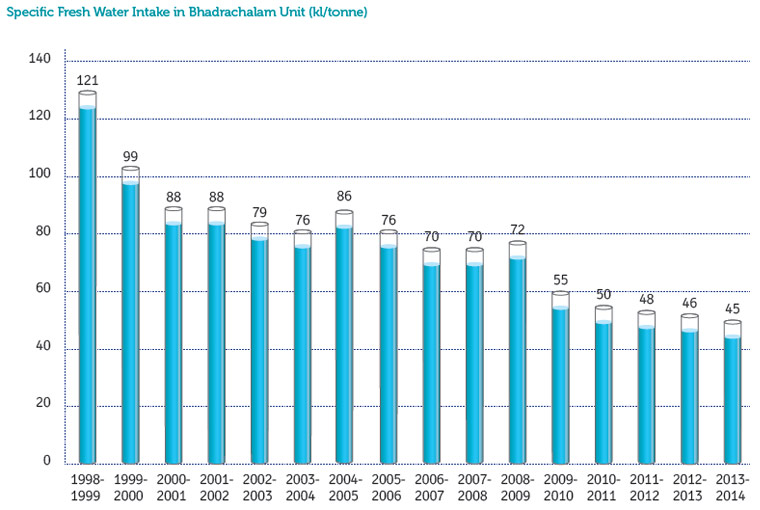

India's largest integrated paper and paperboards mill accounted for 74.6% of the total fresh water intake in ITC. In 2013-14, the Bhadrachalam Unit's freshwater intake was 45.1 kl per tonne of product, a reduction of 2.8% over last year's 46.4 kl/tonne, primarily due to various water conservation initiatives undertaken by the Unit. It is worth mentioning that this surpasses the proposed benchmark standard of 63 kl/tonne by the National Productivity Council (NPC), for large-scale integrated pulp and paper mills. (Reference: Final Report on Development of Guidelines for Water Conservation in Pulp and Paper Sector by NPC, New Delhi, March 2006).

India's largest integrated paper and paperboards mill accounted for 74.6% of the total fresh water intake in ITC. In 2013-14, the Bhadrachalam Unit's freshwater intake was 45.1 kl per tonne of product, a reduction of 2.8% over last year's 46.4 kl/tonne, primarily due to various water conservation initiatives undertaken by the Unit. It is worth mentioning that this surpasses the proposed benchmark standard of 63 kl/tonne by the National Productivity Council (NPC), for large-scale integrated pulp and paper mills. (Reference: Final Report on Development of Guidelines for Water Conservation in Pulp and Paper Sector by NPC, New Delhi, March 2006).

Specialty Papers Unit at Tribeni

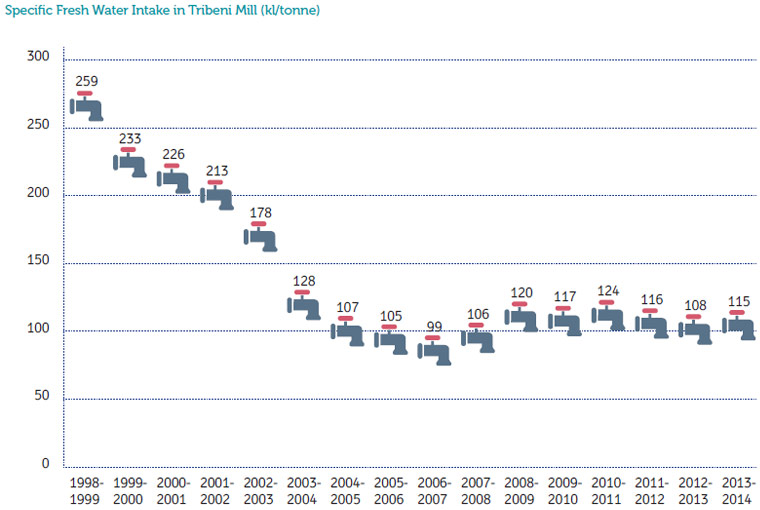

ITC's Unit at Tribeni manufactures specialty paper, which is a water intensive process. The Unit has achieved around 56% reduction of specific freshwater intake per tonne of product during the reporting period, in comparison to 1998-99. However, there is an increase of 6.3% in the specific freshwater intake over the previous year primarily due to the commissioning activities of the new power plant. Additional efforts are underway to achieve further reduction in specific freshwater intake in the Unit.

ITC's Unit at Tribeni manufactures specialty paper, which is a water intensive process. The Unit has achieved around 56% reduction of specific freshwater intake per tonne of product during the reporting period, in comparison to 1998-99. However, there is an increase of 6.3% in the specific freshwater intake over the previous year primarily due to the commissioning activities of the new power plant. Additional efforts are underway to achieve further reduction in specific freshwater intake in the Unit.

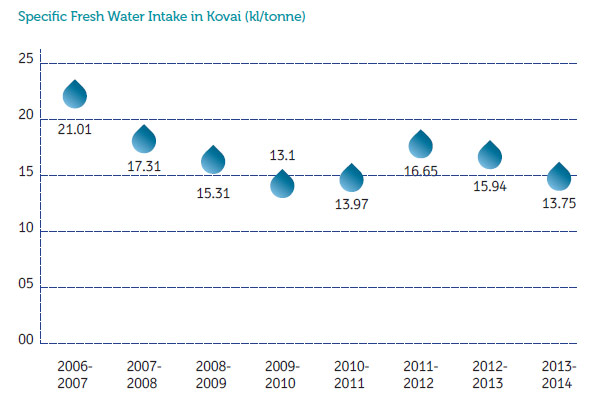

Paperboards Unit at Kovai

The specific freshwater intake (kl/tonne) in the Paperboards & Specialty Papers Unit at Kovai was 34.6% lower than the specific fresh water intake during 2006-07 (the Unit was acquired by ITC in March 2004 and data compilation was started from 2006-07 onwards). Various water conservation measures undertaken by the Unit during the year led to the reduction in specific fresh water intake from 15.94 kl/tonne in 2012-13 to 13.75 kl/tonne in 2013-14.

This specific freshwater intake of 13.75 kl/tonne surpasses the proposed benchmark standard of 19 kl/tonne set by NPC in New Delhi in 2006 for this category of paper mills.

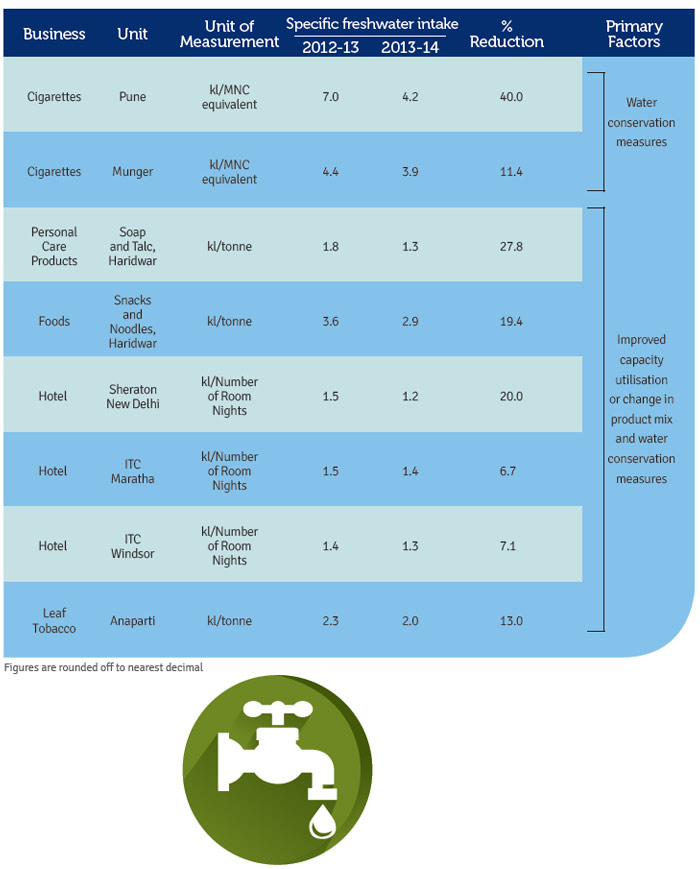

In addition, the following Units have reported significant reduction in specific freshwater intake in 2013-14 as compared to 2012-13:-

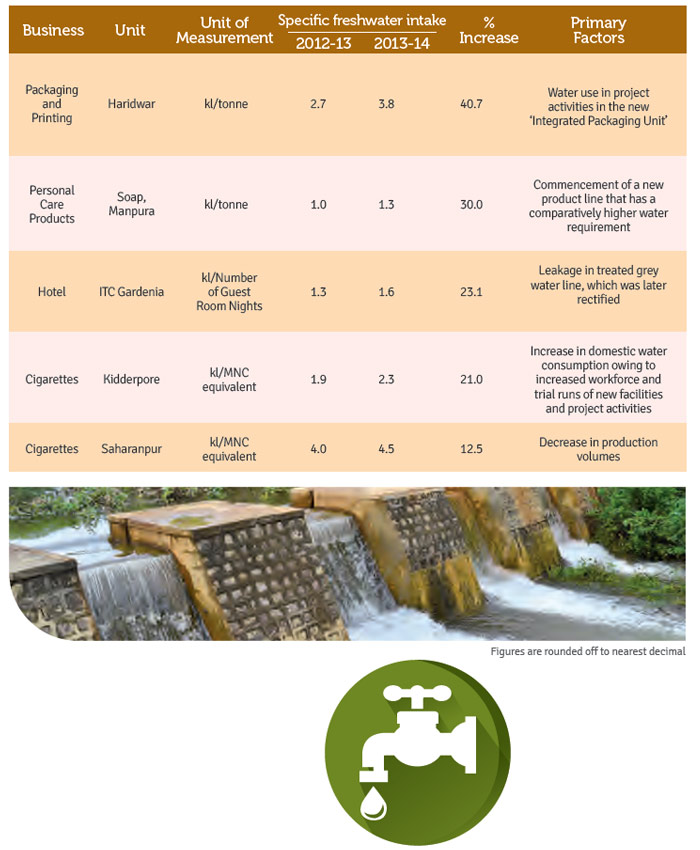

The following Units have reported significant increment in specific freshwater intake in 2013-14 as compared to 2012-13:-

Effluent Discharge

ITC is committed to achieving zero effluent discharge through treating and recycling of all wastewater and harvesting of rainwater on its properties. This not only reduces fresh water intake but also maximises groundwater recharge, reduces run-off etc.

Many ITC Units have already achieved the goal of zero effluent discharge outside the Unit premises. These include: Cigarette Factories at Bengaluru, Saharanpur & Pune, Leaf Processing Units at Anaparti, Chirala & Mysore, Packaging & Printing Unit at Tiruvottiyur, Life Sciences & Technology Centre at Bengaluru, Research Centre at Rajahmundry, Paperboards and Specialty Papers Business Units at Kovai and Bollaram, Personal Care Products Business Unit at Manpura, Lifestyle Retailing Business Unit at Manesar, Hotels Unit ITC Rajputana at Jaipur, and ITC Green Centre at Gurgaon.

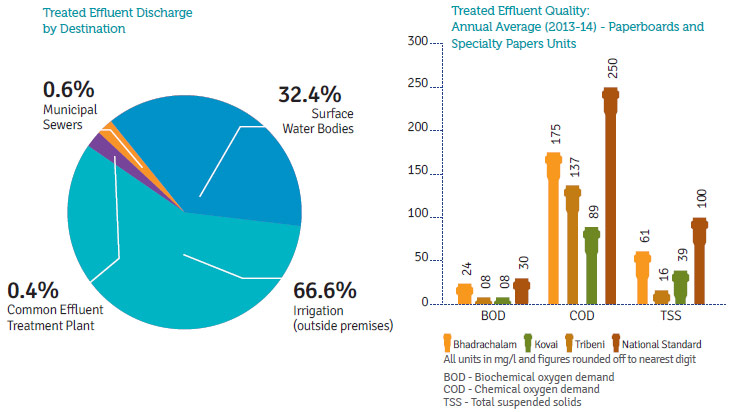

In 2013-14, a total volume of 23.9 million kl of treated effluent was discharged outside the premises by ITC units, out of which 66.6% was used for irrigation by communities in the vicinity. In a nation now confronted with the growing challenges of water security, this treated effluent is a resource that the neighbouring communities increasingly rely upon to meet their irrigation requirements.

The two Paperboards and Specialty Papers Units at Bhadrachalam and Tribeni accounted for 98.64% of total wastewater discharged outside the Unit premises in ITC. The quality of the treated effluent from these Units was far better than the stipulated standards, as depicted below:

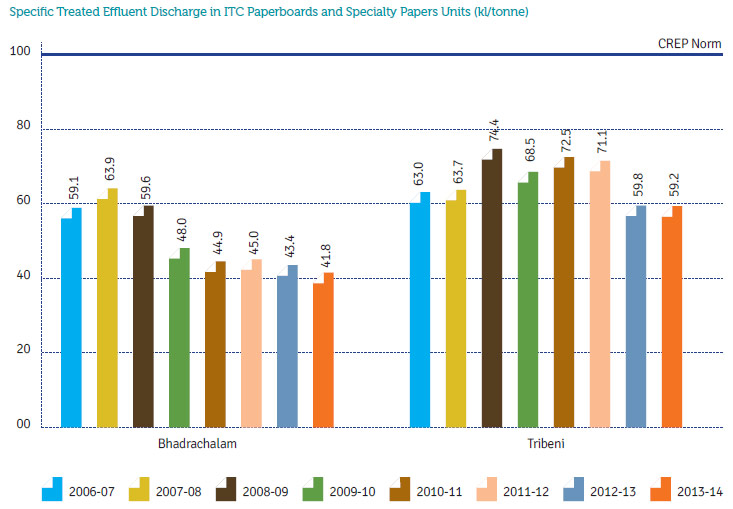

The Bhadrachalam and Tribeni Units have also maintained standards that are well within the norms prescribed by the Corporate Responsibility for Environmental Protection (CREP), a voluntary charter by the Ministry of Environment & Forests and Central Pollution Control Board for large pulp and paper manufacturing units with respect to specific treated effluent discharge.

The National Productivity Council (NPC)'s Report on 'Proposed Standard for Pulp and Paper Industries in India' suggests a benchmark standard of 50 kl/tonne of specific treated effluent discharge for the integrated pulp and paper industry. This is applicable to our Paperboards Unit at Bhadrachalam. The current level of 41.8 kl/tonne at the Bhadrachalam Unit surpasses the above proposed benchmark.

Similarly, the above report suggests a benchmark standard of 15m3/tonne for wastepaper-based pulp and paper mills. ITC's Unit at Kovai, which falls under the wastepaper-based pulp and paper mills category, did not discharge any treated effluent outside its premises this year.

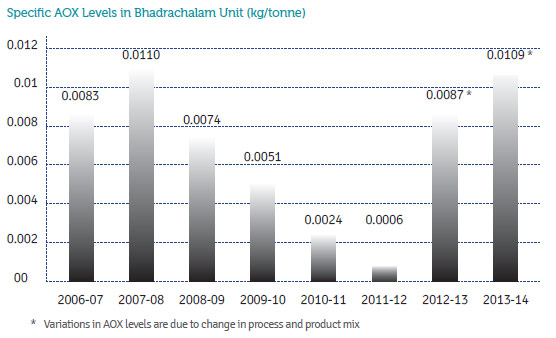

In the current year, the Adsorbable Organic Halides (AOX) level (applicable only to the Bhadrachalam Unit) was 0.0109 kg/tonne of product, which is well below the norm stipulated by Ministry of Environment and Forests (MOEF), national and international benchmark figures as depicted below:

MOEF, National and International Benchmark Standards for Specific AOX Levels in kg/tonne

| kg/tonne | |

| MOEF standard | 1 |

| Indian Paper/Paperboard mills * | 0.46-0.8 |

| European Paper Industries # | 0.029 |

| World Bank Standard ** | 0.25 |

* Average as per Comprehensive Industry Document for Large-Scale Paper Mills, study conducted by Central Pulp and Paper Research Institute, 2007

# CEPI (Confederation of European Paper Industries), Sustainability Report 2011

** World Bank Guideline for New Paper Mills (2007)

Enlarging a Water Positive Footprint

The Company's continued interventions in rainwater harvesting both in the Company premises and socially relevant watershed areas has enlarged our water positive footprint.

The Company's continued interventions in rainwater harvesting both in the Company premises and socially relevant watershed areas has enlarged our water positive footprint.

As on March 31, 2014, ITC's Integrated Watershed Development Projects, covering nearly 1,49,000 hectares of land, support the Water Positive status of the Company for the 12th year in a row. The total rainwater harvesting potential created by the Company so far is over two times the net water consumption by our operations.

The Road Ahead

As water stress is a major risk for many of our Businesses, ITC plans to carry out appropriate hydrological studies at identified water stressed Units to develop a comprehensive understanding of these issues. A pilot study to this effect has been initiated at one of our Units to achieve the following objectives:

Phase I: Detailed assessment of water usage and water quality inside the Unit's premises to comprehend the minimum freshwater withdrawal required to operate the plant. This phase has been completed and measures to optimise water usage are being implemented.

Phase II: Evaluation of water withdrawal and wastewater discharge impacts at the local watershed level. This will enable the Company to understand the impacts of withdrawal from source and discharge of treated effluents by all stakeholders. The specific interventions necessary for ensuring water security for all stakeholders within the defined watershed area can then be identified. This study is presently underway.

Once the final recommendations are available, ITC will engage with other stakeholders to implement necessary projects.

Management Approach

The issue of waste management has assumed critical significance for the country today. Rapid urbanisation, increasing population, higher consumption levels and inadequate infrastructure are putting a severe strain on the ecology. A large amount of wastes being generated today end up in landfills. Apart from the increasing pressures on natural resources, the issue of burgeoning waste also contributes to soil & groundwater contamination and Greenhouse Gas (GHG) emissions, leading to serious concerns of public health, sanitation as well as large scale environmental degradation.

Often considered to be only an urban phenomenon, inadequate waste management today threatens the quality of life throughout India. Heaps of unattended waste, foraged by cattle and rag-pickers alike, have become a common sight both in urban and rural areas of the country.

In alignment with ITC's commitment to reduce its environmental impact and create a positive ecological footprint, the Company has adopted the following approaches on waste management:

1. RESOURCE CONSERVATION

All ITC Units are mandated to reduce specific waste generation through constant monitoring and improvement of efficiencies in material utilisation.

All ITC Units are mandated to reduce specific waste generation through constant monitoring and improvement of efficiencies in material utilisation.

2. SEGREGATION AT SOURCE

All ITC Units are required to ensure that wastes are segregated at source in accordance with Company-defined guidelines. This ensures maximum reuse and recycling of waste.

3. TOWARDS 100% RECYCLING

Each category of waste is individually addressed and tracked to ensure that it can be reused wherever possible, and if not, recycled. This ensures that almost no waste from our businesses lands up in municipal or private landfills.

4. CREATING A POSITIVE ENVIRONMENTAL FOOTPRINT

ITC's Paper and Paperboards Units are encouraged to increase the utilisation of externally generated wastepaper as a source of fibre instead of virgin fibre. Apart from the direct environmental benefits of reduced consumption of power, water and chemicals, this leads to the additional public benefit of encouraging better municipal waste management.

Resource Conservation

In 2013-14, ITC Units generated 7,11,887 tonnes of waste (6,82,405 tonnes in 2012-13). This 4.3 % increase over last year in total waste generated was due to increased production by the Paperboards and Specialty Papers Division (up 7.8%), a business that contributes to 90.8% of the total waste generated by ITC's operations. The increase can also be attributed to the inclusion of data from the Mysore Unit of ITC's Leaf Tobacco Business and ITC Grand Chola of ITC's Hotels Division. However, many business Units have reduced their specific waste generation performance (waste generated per unit of product/service).

ITC's Unit at Bhadrachalam, which accounts for 76.2% of the total waste generated in ITC, has reduced specific waste generation to 1,044 kg per tonne of paper and paperboard in 2013-14 from 1,111 kg per tonne in 2012-13.

According to the Centre for Science and Environment Report, 'All About Paper' (2004), similar paper mills generate around 1,200 kg of solid waste per tonne of product.

A few examples of other ITC Units which achieved significant reduction in specific waste generation are given on the next page.

| Business | Unit | Specific Waste Generation | Unit of Measurement | Percentage Reduction | Primary Factors | |

| 2012-13 | 2013-14 | |||||

| Hotels | ITC Mughal | 7.1 | 3.3 | kg/Number of Room Nights | 53.5 | Process improvement and waste reduction programmes |

| Hotels | ITC Rajputana | 6.8 | 3.3 | kg/Number of Room Nights | 51.5 | |

| Hotels | ITC Sonar | 6.5 | 3.3 | kg/Number of Room Nights | 49.2 | |

| Hotels | ITC Maratha | 11.3 | 6.9 | kg/Number of Room Nights | 38.9 | |

| Hotels | WelcomHotel Sheraton New Delhi | 2.0 | 1.7 | kg/Number of Room Nights | 15.0 | |

| Foods Snacks Unit | Haridwar | 101.2 | 89.1 | kg/tonne | 12.0 | Improved capacity utilisation and process improvement |

Figures are rounded off to nearest decimal

On the other hand, the following Units have reported significant increase in specific waste generation. Though these Units contribute to only 5.2% of the total waste generated within ITC, requisite measures are being implemented to address this issue.

| Business | Unit | Specific Waste Generation | Unit of Measurement | Percentage Reduction | Primary Factors | |

| 2012-13 | 2013-14 | |||||

| Cigarettes | Kidderpore | 0.04 | 0.15 | t/MNCeq | 275.0 | In the previous year, Corrugated Fibreboard Container (CFC) waste was not considered as it was recycled at Leaf Tobacco Business. This year CFC recycling has been done locally and hence included in the waste quantity. |

| Cigarettes | Pune | 0.06 | 0.15 | t/MNCeq | 150.0 | |

| Cigarettes | Munger | 0.11 | 0.15 | t/MNCeq | 36.4 | |

| Cigarettes | Saharanpur | 0.10 | 0.13 | t/MNCeq | 27.3 | |

| Foods | Biscuits, Haridwar | 92.1 | 135.2 | t/MNCeq | 46.8 | Trial runs for new products and introduction of new product variants |

| Packaging and Printing | Munger | 205.5 | 270.1 | kg/tonne | 31.4 | Disposal of one time rain damaged paperboards |

| Packaging and Printing | Haridwar | 250.4 | 314.1 | kg/tonne | 25.4 | Start-up of new product lines in the new 'Integrated Packaging Unit' |

| Personal Care Products | Soap, Manpura | 20.9 | 25.7 | kg/tonne | 22.9 | New product line commissioning activities |

| Paperboards and Specialty Papers | Kovai | 179.7 | 209.5 | kg/tonne | 16.6 | Increased procurement of domestic waste paper as raw material and consequent increase in miscellaneous wastes, and change in product mix |

Figures are rounded off to nearest decimal

| Item | Quantity (tonnes) | Disposal |

| Sludge from effluent treatment plant of Paperboards and Specialty Papers factories | 20047 | To authorised recyclers |

| 19 | Authorised Landfill | |

| 5 | In-house Storage | |

| Empty containers of hazardous chemicals | 430 | Decontaminated and returned to original suppliers |

| Used oil/ waste contaminated with oil/oil soaked cotton waste | 304 | To authorised recyclers |

| 1 | In-house storage | |

| 7 | Incinerated | |

| Used lead acid batteries | 82 | Returned to original suppliers for recycling |

| 13 | In-house storage | |

| Spent solvents/ink/ink sludge/adhesives/ Process waste/Chemical sludge/ Sludge from fuel tanks | 103 | Recycled |

| 284 | Incinerated/or sent to authorised landfills/ stored within the Unit | |

| Biomedical waste (from medical centres within our units) | 2 | Incinerated/Autoclaved |

| E - Waste | 17 | Recycled |

| 3 | In-house storage |

Segregation of Waste

Of the total waste generated at ITC, only 2.9% by weight can be categorised as hazardous waste as per Indian statutes. In 2013-14, 98.4% of this hazardous waste was recycled by external agencies (as illustrated above). The balance 1.6% was disposed of or stored completely in accordance with applicable statutes. In addition, apart from hazardous wastes transported to external treatment sites by authorised transport agencies as applicable, no other hazardous wastes were transported between locations owned or managed by the organisation.

All ITC Units have established systems and procedures to verify the authorisations and licenses of hazardous waste recyclers in order to ensure that these wastes are transported, recycled or disposed of in compliance with regulations and norms. Corporate EHS verifies compliance in each of the Units on a periodic basis.

Waste Destination

The illustration below depicts the final destinations of total wastes generated during 2013-14:

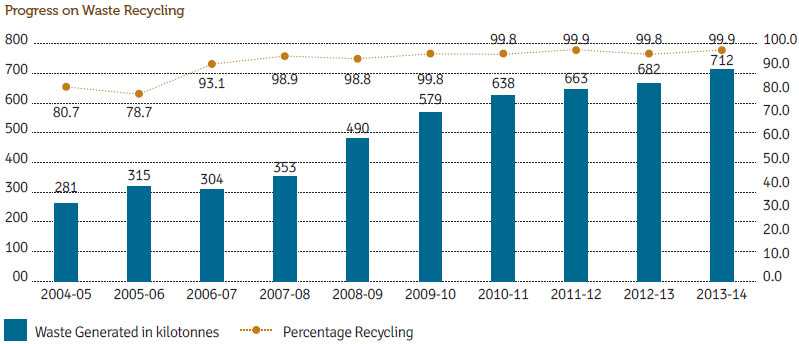

Focussed attention on identifying and tracking of all waste streams as well as their characterisation and quantification have helped ensure the recycling of 99.9% of the total waste generated in all ITC business Units. It is noteworthy that in 2013-14, ITC's Unit at Bhadrachalam, which is India's largest integrated Paper & Paperboards mill, together with the following Units managed to recycle 99.9% of the waste generated.

- Cigarette factories at Munger, Bengaluru, Saharanpur, Kolkata and Pune.

- Paperboards and Specialty Papers Units at Tribeni.

- Personal Care Business Units at Haridwar.

- Foods Business Units at Haridwar (Snacks) and Pune (Snacks and Noodles).

- Leaf Tobacco processing Units at Chirala and Mysore.

- Research Centre at Rajahmundry.

- ILTD Divisional Head Office in Guntur.

- ITC Green Centre at Gurgaon.

- Hotels: ITC Maurya, ITC Maratha, ITC Grand Central, ITC Windsor, ITC Mughal, ITC Gardenia, ITC Sonar, ITC Rajputana and WelcomHotel Sheraton New Delhi.

In 2013-14, ITC also generated 3,28,029 tonnes of fly ash, (46% of total waste in ITC), 100% of which has been utilised for brick making and cement manufacturing.

Waste Used as Raw Materials

As evident above, the high degree of recycling achieved across ITC, together with the use of post-consumer waste by the Paperboards and Specialty Paper Units at Kovai and Bhadrachalam, has enabled the Company to further expand its waste recycling footprint.

| 2007-08 | 2008-09 | 2009-10 | 2010-11 | 2011-12 | 2023-13 | 2013-14 | |

| Total Waste Generated (tonnes) | 3,52,970 | 4,90,180 | 5,78,865 | 6,38,405 | 6,63,796 | 6,82,405 | 7,11,887 |

| Waste Recycled (tonnes) | 3,49,264 | 4,84,287 | 5,77,766 | 6,37,452 | 6,62,978 | 6,81,129 | 7,11,033 |

| Percentage Recycled | 98.9 | 98.8 | 99.8 | 99.8 | 99.9 | 99.8 | 99.9 |

| Un-recycled waste (tonnes) | 3,706 | 5,893 | 1,099 | 953 | 818 | 1276 | 854 |

| External Wastes used as Raw Materials (tonnes) | 1,63,245 | 1,25,337 | 1,25,931 | 1,19,002 | 1,15,414 | 1,18,462 | 1,09,998 |

| Waste Recycling Footprint (%) * | 145 | 124 | 122 | 119 | 117 | 117 | 115 |

*Waste Recycling Footprint (%): (Waste Recycled + external waste

used as raw material) x 100/Total waste generated in ITC

Waste from Supply Chain

As a preliminary step, ITC has accounted for the waste generated in 2013-14 from the operations of exclusive third party manufacturing units catering to the notebooks segment of ITC's Education and Stationery Products Business, as well as ATC Limited, our associate company. This information is detailed below. This coverage will be progressively expanded in the future.

| Supply Chain Members | Total Waste Generated (in tonnes) | % Recycled |

| Exclusive TPM Units for Notebooks segment | 2625 | 95.9 |

| ATC Limited | 616 | 99.9 |

The Road Ahead

ITC will continue to focus on improving material efficiencies and reducing specific waste generation in addition to continued efforts on total recycling of waste generated within its premises. In line with ITC's Policies on Life-Cycle Sustainability and Responsible Sourcing, ITC will engage with supply chain partners to build awareness in reducing or recycling of waste generated in the years to come. The existing Wealth out of Waste (WOW) programme will be expanded to address the issue of sustainable livelihoods for people engaged informally in the waste business, while at the same time providing a solution to tackle the challenge of post-consumer waste. In addition, as part of the WOW initiative, ITC is also exploring the usability of compact boards made out of plastic waste (the dominant component in municipal wastes) for furniture, etc. Field trials for the same are currently underway. Based on the results of these field trials, commercial applications for these compact boards will be taken up in a phased manner. This would go a long way in further augmenting the incomes of people informally engaged in waste management.

Management Approach

ITC's products and services can be broadly classified into the following categories:

1. FMCG (B to C) Products

Cigarettes, Foods, Personal Care Products, Education and Stationery products, Matches and Agarbatti.

2. INDUSTRIAL SUPPLIES AND EXPORTS

Paper, Paperboards, Packaging, Leaf Tobacco, etc.

3. Services

Hoteliering and Information Technology.

Since ITC is vertically integrated to a large extent, it provides opportunities for successive value addition within the system for several categories of products such as paperboards for packaging. This integration provides the Company unique opportunities to establish synergies thereby minimising environmental impact through the optimum utilisation of raw materials, recycling/ reuse of wastes as well as optimum logistics and transportation. These synergies, significantly reduces the environmental footprint of ITC's products and services.

We have completed studies on life cycle assessment of some of our products in Paper, Paperboards & Packaging and Lifestyle Retailing Businesses. This has helped in identifying broad areas for improvements as well as building internal competencies to enable us to expand these studies to other products and services.

All ITC Units continue to pursue efficient use of natural resources through extensive R&D and waste elimination/reduction through process management. In addition, the recent Board approved Policies on Life Cycle Sustainability and Responsible Sourcing now provide the necessary focus on sustainable sourcing of raw materials to ensure their long-term availability. These policies will be implemented across all Businesses starting 2014-15 in a phased manner.

Performance

A very significant proportion of raw materials in ITC businesses are sourced from agricultural farms and plantations. Our initiatives in developing large scale social and farm forestry plantations, integrated watershed management and empowering marginal farmers have all helped in improving the overall sustainability of the value chain. In 2013-14, ITC consumed over 29,00,000 tonnes of materials, out of which close to 98% were from agricultural farms and plantations which are renewable.

Responsible Sourcing of Wood Fibre

Wood is a major source of fibre for the paper and paperboards industry. Availability of wood remains a challenge and can be a serious sustainability concern, especially in a country with limited natural resources and acute income inequities.

In 2013-14, approximately 48% of the total fibre requirements of ITC's Paperboards and Specialty Papers Division was met by the pulp manufactured at Bhadrachalam, another 22% came from recycled fibre, processed at ITC's Units in Kovai and Bhadrachalam, and the balance 30% was imported pulp. For wood pulp manufactured at the Bhadrachalam Unit, 72% of the wood was sourced from our social and farm forestry initiatives, while the balance 28% wood was sourced from known and legal domestic and imported supplies. 100% of the fibre used for operations at the Kovai Unit was sourced from recycled fibre. Internal R&D has produced high yielding, site specific, disease resistant eucalyptus and subabul clones supported by extensive knowledge of plantation management practices which provide a robust foundation for the social and farm forestry programme. During the year, ITC distributed 138 million high quality saplings to farmers and close to 21,000 additional hectares were planted under ITC's social and farm forestry initiatives.

Apart from the obvious benefits of increasing the green cover, plantation on wastelands under the social forestry programme also directly contributes to in-situ moisture conservation, ground water recharge and significant reduction in topsoil losses caused by wind and water erosion. In addition, as a result of the leaf litter from multi-species plantations and the promotion of leguminous intercrops, erstwhile degraded soils are being constantly enriched.

Forest Stewardship Council Certifications

All the four Units of ITC's Paperboards and Specialty Papers Division i.e Bhadrachalam, Bollaram, Kovai and Tribeni, which received the prestigious 'FSC Chain of Custody' Certification in 2009, are maintaining their status.

The FSC (Forest Stewardship Council) is an independent, non-governmental, not-for-profit organisation established to promote the responsible management of the world's forests and is recognised as the gold standard in the wood certification for ethical and legal sourcing. The FSC is represented in more than 107 countries around the world, and is the most widely accepted and respected amongst forest product certification schemes.

ITC's Paperboards and Specialty Papers Division can now supply FSC certified paper /paperboards from all its four Units with the FSC claim of 'FSC Mixed' or 'FSC Recycled'. The FSC logo endorses that the product/packaging is from legal, sustainable and well managed sources and thereby provides confidence to customers. The FSC certification for ITC's Paperboards and Specialty Papers Units exemplifies the organisation's continued commitment to sustainable business practices and to the building of an inclusive and secure future for its stakeholders.

In continuation of its commitment to expand its scope, the organisation, till date, has facilitated the certification of 22,804 hectares of plantations owned by more than 24,000 small and marginal farmers under the FSC Forest Management Certification.

Agri-commodities

ITC's Agri Business primarily engages in sourcing of agri-commodities like wheat, coffee, potato, shrimps, soya and processed fruits, sourced and supplied based on customer requirements of quality, quantity and packaging. Consistent investments are made towards strengthening capability through multiple sourcing models, customised and identity preserved supply chain infrastructure and network, processing and warehousing tie-ups and technology enabled systems and processes. The Business also works closely with farmer groups to develop identified geographies for certified and organic crops. These investments coupled with deep understanding of agriculture, and the reach of the ITC e-Choupal network, provides the opportunity to offer a wide range of reliable and consistent solutions to customers that are efficient and effective.

The Road Ahead

In the coming years, we plan to carry out more life cycle assessment studies of products/services to evaluate the environmental impacts at the various life cycle stages, which would help us in identifying opportunities for further improving their environmental attributes. In line with the Board approved Policies on Life Cycle Sustainability and Responsible Sourcing, relevant systems and procedures will be progressively implemented across ITC Businesses towards sustainable sourcing of raw materials.

Moreover, for sustainable sourcing of wood pulp, ITC is planning to bring in more plantation areas under the FSC – Forest Management certification in future. This certification should help bring in better environmental practices and improved social benefits to the local communities.

Management Approach

ITC recognises that the preservation and nurture of biodiversity is essential to ensure the long-term sustainability of not only farming communities but the agricultural sector itself. ITC has accordingly implemented several initiatives to address the issues of revival and nurture of native species of flora and fauna, thereby leading to large-scale replenishment of natural resources and ensuring a sustainable future for the communities residing in the Company's catchment areas.

Biodiversity Risk and Opportunity Assessment

One of ITC's large agri business divisions has undertaken a detailed risk analysis of its impacts on biodiversity. It has spearheaded the implementation of the Biodiversity Risk and Opportunity Assessment (BROA) process across its entire operating region. For this purpose the Business has partnered with Earth Watch Institute, UK, an international non-profit organisation specialising in Biodiversity Risk & Opportunity Study. The objective is to identify the impacts and dependencies of crop development on terrestrial, soil and aquatic biodiversity in agricultural landscapes; assess and prioritise the risks and opportunities arising from those impacts and dependencies; produce Action and Monitoring Plans for the business to address them. The agricultural landscape level approach would encompass not only farm sites and immediate area of production, but also the wider features that agricultural production depends upon. For this assessment, ITC has engaged with many internal and external stakeholders including farmers, local communities, Department of Agriculture, Forest Department, local Universities, NGOs and suppliers. The first stage of the BROA has been completed in select agricultural landscapes in Mysore District and is currently underway in other operating areas of the business. Based on the findings of this analysis, ITC will put in place systems and processes to address the concerns therein.

Social Forestry

ITC has successfully launched a programme to conserve and improve biodiversity in its Social Forestry and Farm Forestry catchment areas, which would not only revive and enhance native floral and faunal biodiversity, but also contribute to livelihood and employment generation. ITC has spearheaded this programme to develop biodiversity plots by motivating local communities to plant native tree species, implement soil and water conservation measures, and adopt livelihood and employment generation activities through pisciculture, apiculture and other related activities. In the past two years, ITC has developed 9 biodiversity plots involving farmers and community members covering a total area of 56.28 acres in Khammam, East Godavari, West Godavari & Visakhapatnam districts of Andhra Pradesh. This initiative has helped in conserving more than a thousand floral and faunal species. Many species of birds have started nesting in the area, which has also become a breeding ground for reptiles, amphibians and butterflies. These biodiversity plots have also helped in improving ground water level and soil fertility thereby enhancing the livelihood generation opportunities of local communities.

Revival of Commons and Biodiversity Conservation Plots

The maintenance and nourishment of common pasturelands assume critical significance for rural communities. Livestock is not only a means to a secondary income, but also a safety net, especially in times of hardship like drought or floods. In that respect pasturelands become a common property of villages. However changes in land use and the 'Tragedy of the Commons,' have put these pasturelands in constant threat of encroachment and degradation, thereby adversely affecting the communities dependent on them.

ITC's Watershed Development Programme in Kalyanpura in Rajasthan led to the revival of biodiversity in the area as well as greening of arid pastures. To address the issue of natural resource management in the drought-prone area, ITC forged a unique public-private-community partnership with the Government of Rajasthan and the Foundation for Ecological Security (FES) and launched an integrated watershed development project in 2007. At the closure of the project in 2010, ITC had treated 5,171 hectares in five Gram Panchayats, covering 19 villages.

Greening Commons

An important part of the project was to protect the pastures to regenerate the root stocks of native species. The project laid special emphasis on developing the commons and planted 1,000 hectares with native species and grass. The saplings were developed from seeds collected from the surrounding areas to maintain the nativeness of the species.

An important part of the project was to protect the pastures to regenerate the root stocks of native species. The project laid special emphasis on developing the commons and planted 1,000 hectares with native species and grass. The saplings were developed from seeds collected from the surrounding areas to maintain the nativeness of the species.

Soil and moisture conservation measures, drainage line treatment and greening of pastureland led to the flourishing of biodiversity in the project area. To measure the impact of the project initiative, ecological surveys, covering different seasons, were carried out. According to the surveys, the vegetation in the project area showed considerable improvement. The project demonstrated that in just three years there was a marked change in species richness, density, diversity and regeneration.

It was noted that plant diversity and density were higher outside the forest areas, demonstrating the value of the project interventions in the pastures of the Kalyanpura watershed. Pastures recorded 54 species (maximum richness), compared to agriculture land or forests. In the grasslands, among the 10 tree species recorded, mature trees comprised three species, while regeneration was represented by six species. In contrast, there was no mature tree in the forestland, while regeneration was represented by only two of the eight tree species documented in this land use.

The baseline data for faunal biodiversity was collected for birds, which showed a doubling in their species, from 40 to 86, including migratory birds.

The project demonstrated that a well-planned watershed development programme can nurture and revive biodiversity. The diversity of flora and fauna status is crucial for any natural and productive ecosystems as it provides ecological services, which strengthen watershed development. Though ecological restoration is a long-term process, the results of this project show what is possible in a short span of time if field-specific approaches are applied and implementation is done in a rigorous manner.

The Road Ahead

Based on the results of the BROA study in agricultural landscapes as well as the outcomes of the implementation of agro-forestry and bio-diversity conservation models, ITC would progressively delineate a biodiversity strategy by combining elements related to substantial biodiversity conservation and improvement, as well as prevention, management, and remediation of damage to natural habitats (if any).