-

Category: Environment

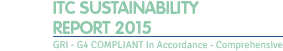

Continued economic progress and business sustainability are today challenged by natural resource depletion with its consequent impacts on long term energy security. Energy availability, accessibility and price volatility are expected to be amongst the biggest developmental challenges for India, where around 600 million1 people lack reliable access to electricity. Extreme energy price volatility has been identified as a significant global risk in the World Economic Forum (WEF) Report on Global Risks 2015, which will exert even more pressure on developing economies like India. ITC has mapped its challenges on the basis of existing as well as the evolving energy scenario and has strategised its response as follows:

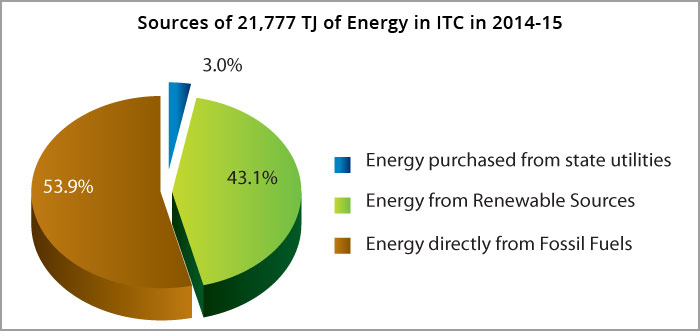

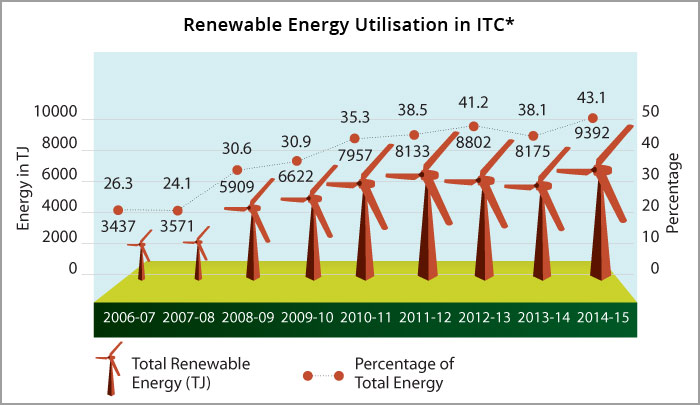

In 2014-15, ITC Units consumed 21,777 Terra Joules (TJ) of energy, which shows a marginal increase of around 2% in the total energy consumption as compared to the previous year (21,433 TJ in 2013-14).

The increase in total energy consumption can be attributed primarily to the inclusion of the following Units / activities into the reporting boundary – Snacks and Noodles Unit of Foods Business at Malur (Karnataka), clonal plantation development activities of Paperboards and Specialty Papers Business at Bhadrachalam, ITC Grand Bharat, Gurgaon and My Fortune Bengaluru of the Hotels Business, together with units of subsidiary companies, namely Classic Golf Resort in Gurgaon, ITC Kakatiya in Hyderabad and Fortune Resort Bay Island in Andaman and Nicobar Islands. The marginal increase in total energy consumption despite reporting boundary expansion has been achieved through better capacity utilisation and concerted efforts on energy conservation implemented across several ITC Units.

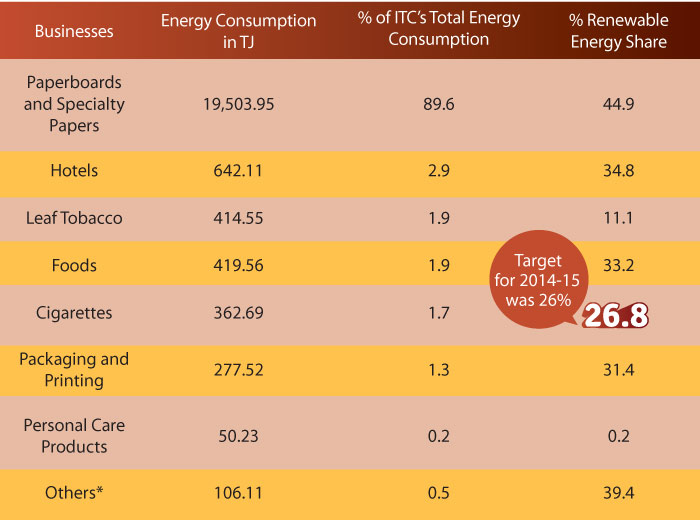

*Others include Agri Business, Lifestyle Retailing Business Unit in Manesar, Classic Golf Resort – a subsidiary unit in Gurgaon, ITC Infotech, ITC Life Sciences & Technology Centre and large offices.

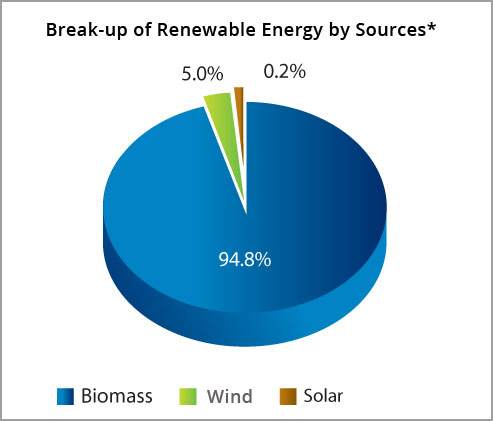

Increase in renewable energy utilisation in 2014-15 from 2013-14 is predominantly due to two factors:

Substantial improvements in specific energy performance were achieved at many of the Units by a focused approach on energy conservation through rigorous third party audits and implementation of the viable recommendations, coupled with better capacity utilisation. As a result of implementation of energy conservation measures, a total saving of 145 TJ in energy consumption has been achieved in 2014-15.

The LEED® Platinum rating accorded to all of ITC's luxury hotels (certification is in progress for ITC Grand Bharat which was opened recently), making it the greenest luxury hotel chain in the world, implies a significant reduction in specific energy consumption with respect to conventionally designed hotels. ITC hotels are not only energy efficient by design but also conserve fossil fuels - with several of ITC's hotels sourcing more than 50% of their electrical energy requirements from wind farms. In order to continually reduce ITC's environmental footprint, green features are integrated in all new constructions and are also being incorporated into existing hotels, manufacturing units, warehouses and office complexes during retrofits.

In order to continually improve on energy performance, ITC Businesses have set voluntary specific energy reduction targets. Accordingly targets have been set at the Unit level for maintaining this performance.

Since Units of Paperboards and Specialty Papers Business account for 89.6% of ITC’s total energy consumption, greater focus is directed towards the energy performance of each manufacturing Unit of this business, performance of which against the targets are as follows:

| Paperboards and Specialty Papers Business |

|

Unit of Measurement | Comparison against target | Comparison against last year | Primary Factors | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bhadrachalam | 31.2 | 30.6 | 31.4 | GJ/MT | 2.6% higher | 0.6% increase |

- Non availability of wind power from own wind farms due to interstate wheeling problems between states of Andhra Pradesh and Telangana - This non-availability of electricity had to be compensated by electricity generated in-house (with attendant auxiliary consumption and conversion loss from fuel to energy) - Increase in pulp generated in own pulp mill by 10% - Commissioning and stabilisation of new lime kiln |

||||||

| Kovai | 13.8 | 13.5 | 11.6 | GJ/MT | 14.1% lower | 15.9% decrease | Improvement in boiler efficiency | ||||||

| Tribeni | 47.5 | 46.6 | 38.0 | GJ/MT | 18.5% lower | 20.0% decrease | Replacement of 2 old boilers and turbines with new boiler and turbine resulting in system efficiency improvement | ||||||

| Bollaram | 0.8 | 0.8 | 0.8 | GJ/MT | Same | Same | |||||||

For computation methodology of energy consumption within organisation, please refer to Quantification Methodologies: Energy and GHG Emissions

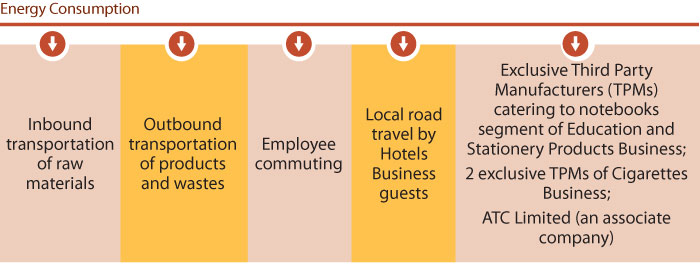

During 2014-15, ITC has expanded the upstream boundary of energy accounting. Accordingly 2558 TJ of energy consumed outside of the organisation has been accounted for during the year.

For computation methodology, please refer to Annexure - Quantification Methodology: Energy and GHG Emissions.

Quality of data continues to be a challenge in the third party manufacturing facilities of Education and Stationery Products Business. Capacity building and regular review of performance data will continue in order to improve the data quality in the coming years. The boundary of accounting will be progressively expanded in the years to come, based on ITC's ability to overcome challenges with regard to data quality.

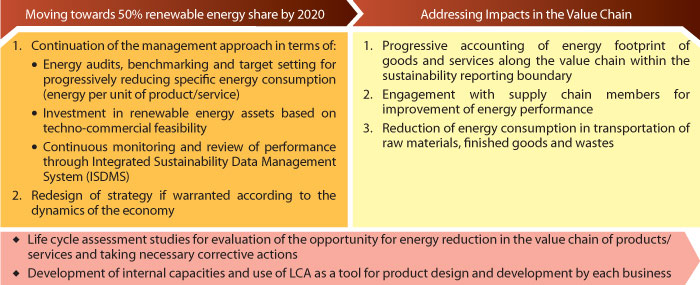

With an objective to evaluate the impacts in the value chain and to identify additional areas for improvement, in 2010 ITC initiated the life cycle assessment (LCA) for its products. So far life cycle assessments of products from Paper, Paperboards & Packaging and Lifestyle Retailing Businesses have been carried out which have helped in identifying broad areas for improvements as well as building internal competencies for such type of studies. These assessments have been followed up with detailed studies which in turn have provided concrete solutions towards more efficient packaging designs, loading efficiencies and consequent reduction in transportation costs / GHG emissions/ energy use.

Going forward, ITC intends to undertake more LCA studies for evaluating hotspots in the value chain of its products and services and identify further opportunities for optimisation.