-

Category: Environment

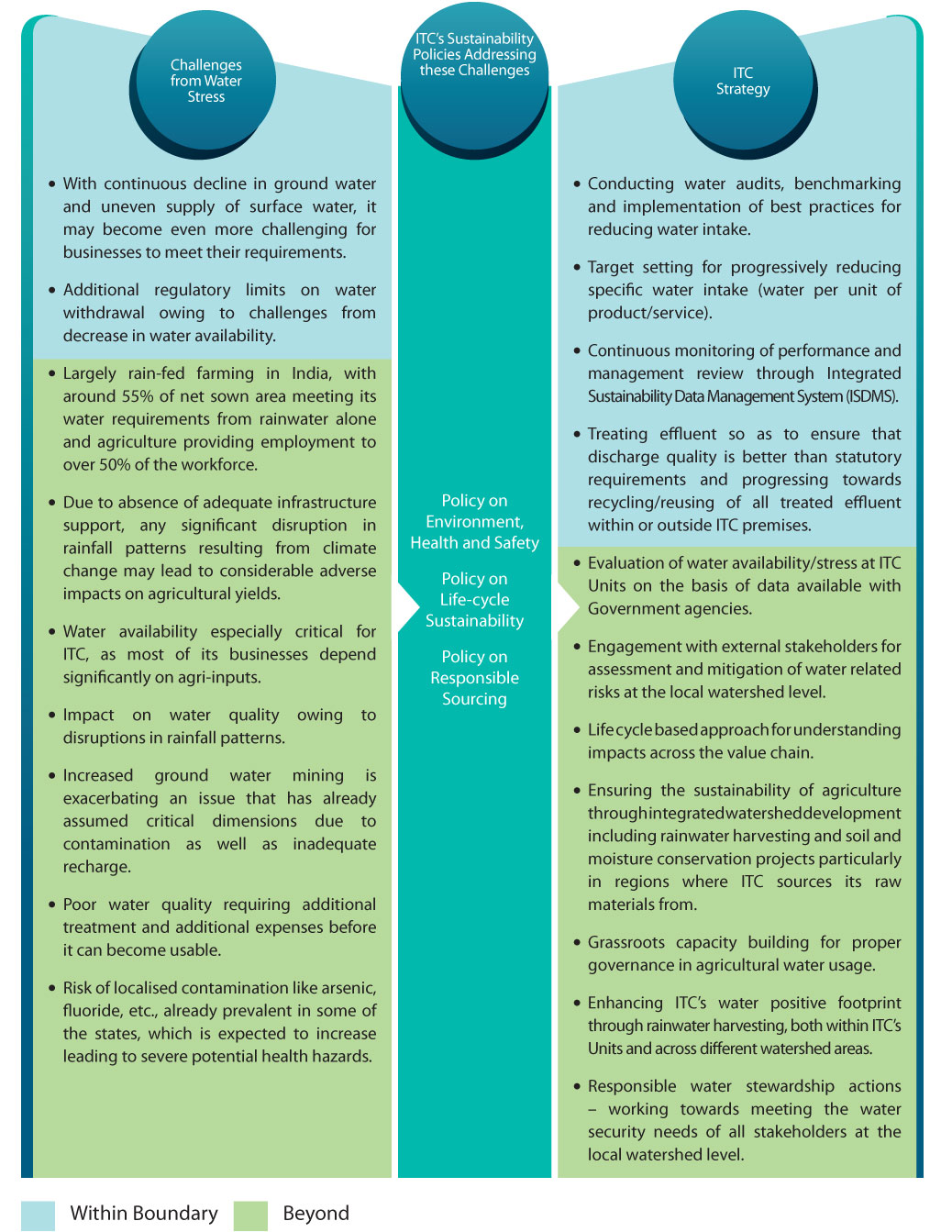

Global water requirements are projected to exceed available sustainable water supplies by 40% by 20301. The issue of water crisis plagues large parts of the world including Africa, parts of North America and Asia. India is particularly vulnerable to water stress given the rapid urbanisation and industrialisation at a time when rainfall patterns are seeing disruption and snow fed rivers are being threatened both by retreating glaciers and geopolitical pressures on diversion of headwaters of rivers originating in the Tibetan Plateau. ITC has sought to engage actively with multilateral agencies like the World Business Council for Sustainable Development (WBCSD), World Resources Institute (WRI), International Water Management Institute (IWMI) etc. to share experiences and also improve understanding of the complex social and technical issues related to water. ITC has also actively supported the development of the India Water Tool as a working group member, an activity coordinated by the WBCSD. This tool permits a first level analysis of water risks across the country, an issue that is becoming increasingly real in the Indian context. ITC, through its deep and long-standing relationship with rural India has first-hand insights of what water scarcity and climate change means to the marginal farmers of India.

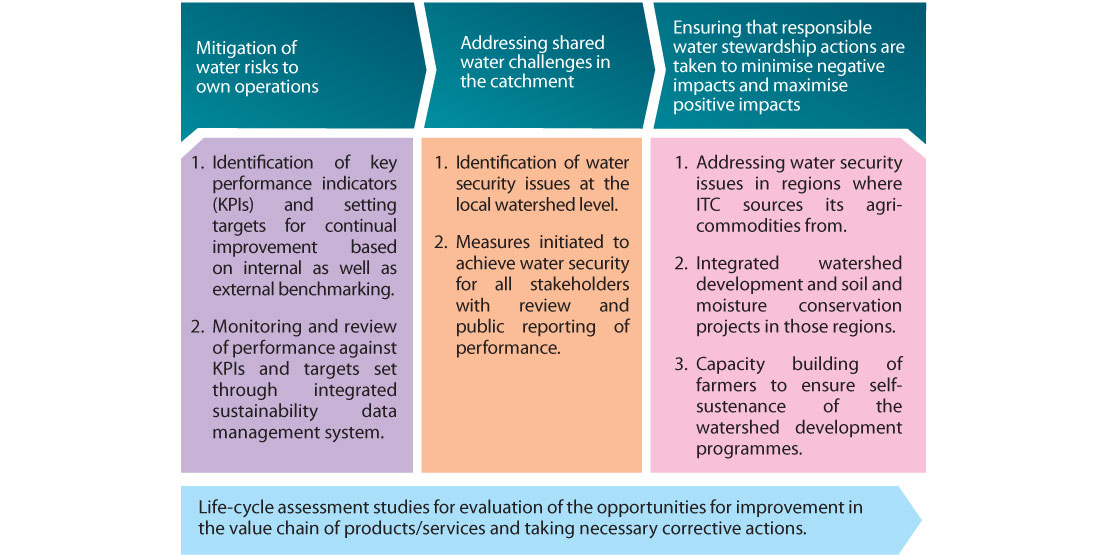

As a proactive and responsible Corporate citizen, ITC has invested significantly in integrated watershed and soil management programmes that focus on institution building and participative management of water resources by farmers. As a next step ITC is in the process of fine tuning a long term strategy for ensuring water security at the localised watershed level for all stakeholders and for all operating units located at identified high water risk areas.

1 Source: Charting our Water Future, Report by 2030 Water Resources Group, 2009

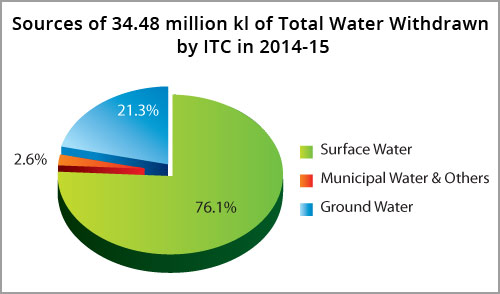

In 2014-15, ITC Units withdrew 34.48 million kilolitres (kl) of water, an increase of only 2% over the previous year (33.73 million kl in 2013-14) despite expansion in reporting boundary. This performance is attributable to the ongoing initiatives undertaken towards water conservation across ITC Units.

Of the 34.48 million kl of total water withdrawn, 76.1% of water resources were sourced from rivers, 21.3% from ground water sources and only 2.6% from municipal and other water sources.

The increase in total water intake can be attributed primarily to the inclusion of the following Units / activities into the reporting boundary - Snacks and Noodles Unit of Foods Business at Malur (Karnataka), clonal plantation development activities of Paperboards and Specialty Papers Business at Bhadrachalam, ITC Grand Bharat, Gurgaon and My Fortune Bengaluru of the Hotels Business, together with Classic Golf Resort in Gurgaon, ITC Kakatiya in Hyderabad and Fortune Resort Bay Island in Andaman and Nicobar Islands being units of subsidiary companies.

Although with the reporting boundary expansion, there has been an increase in total water withdrawal by ITC, focused efforts by all Units to reduce intake by conducting water audits, benchmarking and adopting leading practices facilitated the reduction of specific water intake as illustrated in the following sections.

In order to maintain its performance, ITC Businesses have set voluntary specific water intake reduction targets at the Unit/ Business level.

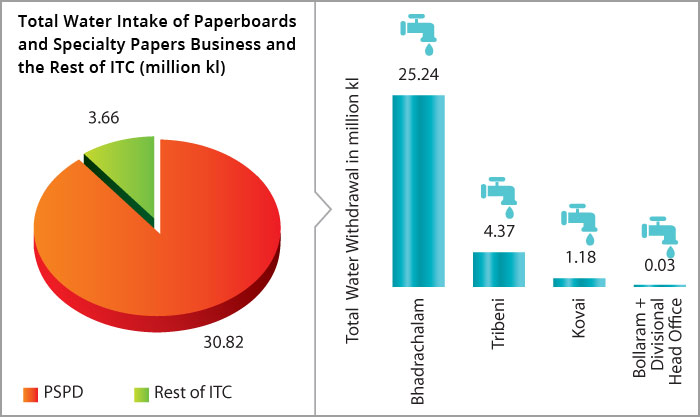

Considering the fact that Paperboards and Specialty Papers Business Units together accounted for around 89% of total water intake of ITC as demonstrated below, it is logical that significant efforts have been focused on the performance of the Units under this Business.

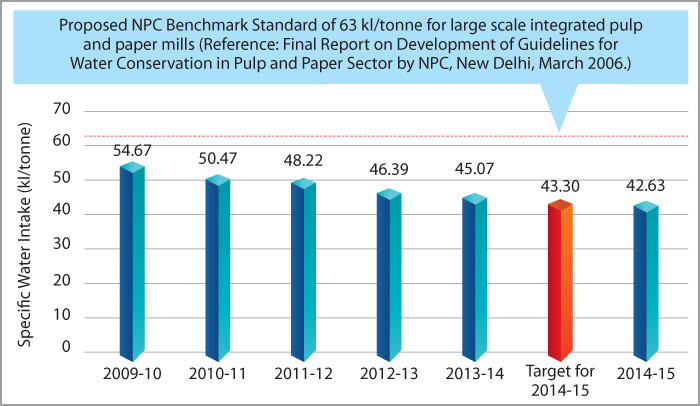

India's largest integrated paper and paperboards mill accounted for 73.2% of the total fresh water intake in ITC. In 2014-15, the Bhadrachalam Unit's freshwater intake was 42.6 kl per tonne of product, a reduction of 5% over the previous year's 45.1 kl/tonne, primarily due to various water conservation initiatives undertaken by the Unit e.g. pipeline modification for increasing usage of paper machine back water, optimisation of water needed for pulp dilution etc. The persistent efforts of the Unit towards water conservation are evident in the consistently decreasing trend of specific water intake as depicted below.

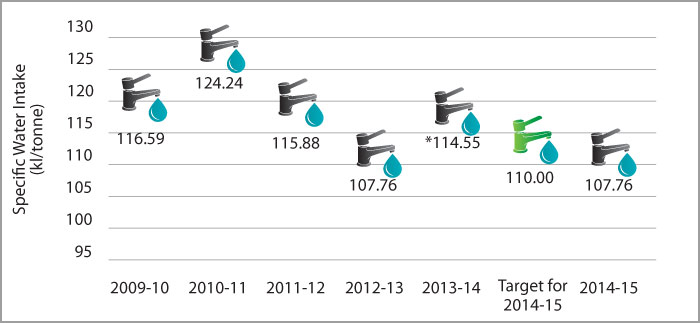

ITC's Unit at Tribeni manufactures specialty paper, which is a water intensive process. The Unit has achieved around 6% reduction of specific water intake per tonne of product during the reporting period over the previous year primarily due to the initiatives undertaken to achieve reduction in specific water intake like increase in recovery of paper machine back water and reuse in the machine, removal of additional perforated showers for wire section of paper machine etc.

*Increase of 6.3% in 2013-14 over the previous year was primarily due to the commissioning activities of the new power plant at Tribeni.

Note: There is no specific NPC benchmark standard for Tribeni

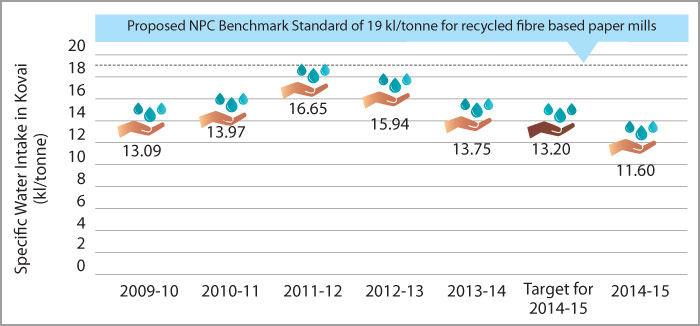

Water conservation measures including increased recycling of treated effluent and use in process, installation of new cooling tower in board machine etc. undertaken by the Unit led to the reduction in specific water intake from 13.75 kl/tonne in 2013-14 to 11.60 kl/tonne in 2014-15.

The target of 0.48 kl/tonne for 2014-15 could not be achieved as decrease in production resulted in specific water intake of 0.53 kl/tonne (actual performance was 0.52 kl/tonne in 2013-14).

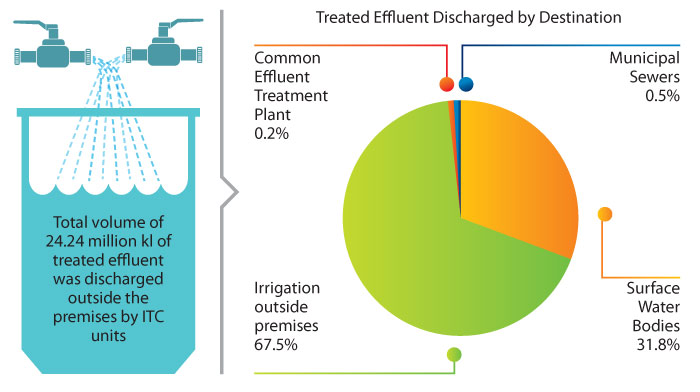

The two Paperboards and Specialty Papers Units at Bhadrachalam and Tribeni accounted for 98.9% of total wastewater discharged outside Unit premises in ITC and 67.8% of the water discharged outside from these two Units was utilised for irrigation purpose. Therefore specific focus has been accorded to the performance of these 2 Units in terms of treated effluent discharge volume as well as quality.

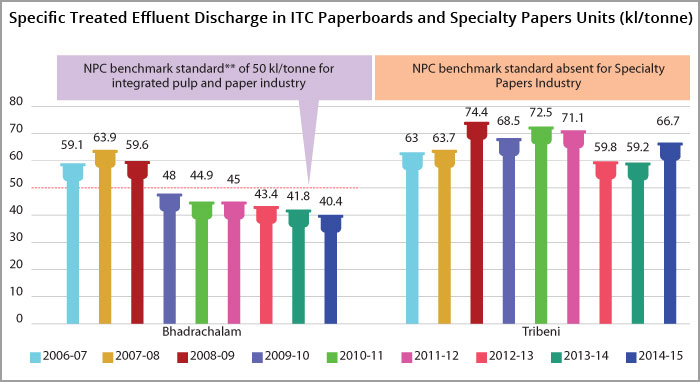

**Reference: National Productivity Council (NPC)'s Final Report on Development of Guidelines for Water Conservation in Pulp and Paper Sector by NPC, New Delhi, March 2006.

Bhadrachalam Unit has been reaping the benefits of initiatives undertaken towards recycling of treated effluent as is evident from the continually decreasing trend of specific treated effluent discharged. For Tribeni Unit, the specific treated effluent discharged has increased from 59.2 kl/tonne to 66.7 kl/tonne. This is due to the installation of a new boiler, which required additional treatment to meet specified water quality standards and resulted in increased discharge of treated effluent in 2014-15 with respect to 2013-14.

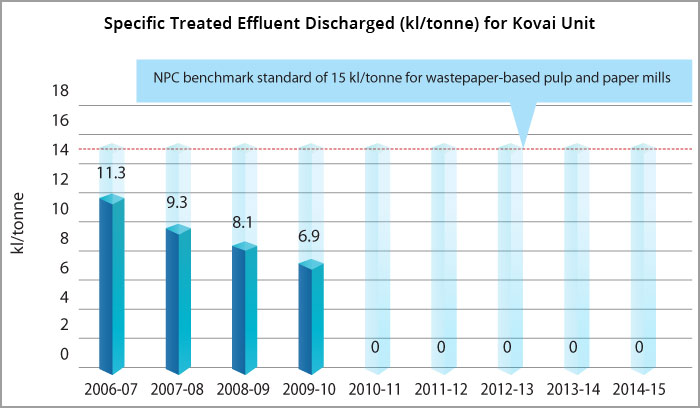

Since 2010-11, the wastepaper-based pulp and paper mill at Kovai has not discharged any treated effluent outside its premises.

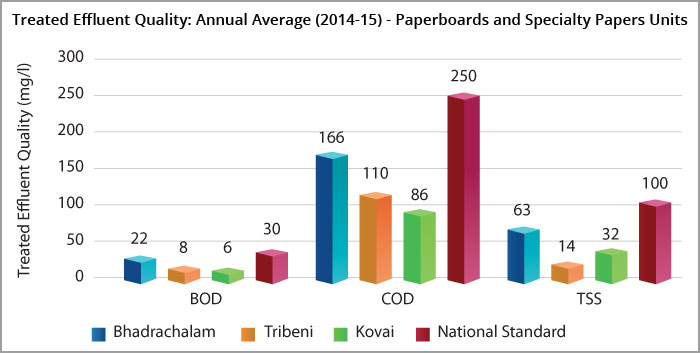

The quality of the treated effluent from Paperboards and Specialty Papers Units was far better than the stipulated standards in India:

In addition, the quality of the treated effluent from Bhadrachalam Unit was comparable with European standards:

| Parameters | Bhadrachalam (kg/tonne of finished product) |

European Paper Industries# (kg/tonne of finished product) |

|---|---|---|

| BOD | 0.90 | 0.816 |

| COD | 6.69 | 5.713 |

# Reference: Confederation of European Paper Industries (CEPI) Sustainability Report 2005 reported the average specific BOD and specific COD values for European Paper Industries in 2002; CEPI Sustainability Report 2013 indicated the reduction in specific AOX value for European Paper Industries from 2002 to 2012.

Another critical parameter applicable only to ITC's Bhadrachalam Unit is the level of adsorbable organic halides (AOX) generated during the bleaching process. These compounds are formed as a result of reaction between residual lignin from wood fibres and chlorine compounds used for bleaching. Depicted below is the specific AOX level for Bhadrachalam unit for the year 2014-15 showing that the level is well below the norm stipulated by Ministry of Environment, Forest and Climate Change (MoEFCC) as well as national and international benchmarks:

| Reference | Specific AOX Level in Kg/tonne of finished product | |

|---|---|---|

| Bhadrachalam Unit | 0.0097 | |

| MoEFCC standard | 1 | |

| Indian Paper/Paperboard mills | Average as per Comprehensive Industry Document for Large-Scale Paper Mills, study conducted by Central Pulp and Paper Research Institute, 2007 | 0.46-0.8 |

| European Paper Industries | Confederation of European Paper Industries (CEPI) Sustainability Report 2005 reported the average specific AOX value for European Paper Industries in 2002; CEPI Sustainability Report 2013 mentioned the reduction in specific AOX value for European Paper Industries from 2002 to 2012 | 0.019 |

| World Bank Standard | World Bank Guideline for New Paper Mills (2007) | 0.25 |

ITC is committed to achieving zero effluent discharge through treating and recycling of all wastewater and harvesting of rainwater on its properties. This not only reduces water intake but also maximises groundwater recharge, reduces run-off etc. In 2014-15, the following Units achieved the goal of zero effluent discharge.

Cigarette Factories at Bengaluru, Saharanpur & Pune, Leaf Processing Units at Anaparti, Chirala & Mysuru, Packaging & Printing Unit at Tiruvottiyur, Snacks and Noodles Unit at Malur, Life Sciences & Technology Centre at Bengaluru, Research Centre at Rajahmundry, Paperboards and Specialty Papers Business Units at Kovai and Bollaram, Personal Care Products Business Unit at Manpura, Lifestyle Retailing Business Unit at Manesar, Hotel Units ITC Maratha in Mumbai, ITC Rajputana at Jaipur, ITC Grand Bharat and ITC Green Centre at Gurgaon

With the intent of progressing towards water stewardship, ITC has started carrying out appropriate studies at identified Units to develop a comprehensive understanding of issues involved. A pilot project to this effect has been initiated at one of ITC's surface water intensive Units:

In line with the Board approved Policies on Life cycle Sustainability and Responsible Sourcing, in 2014-15, ITC has initiated the process of accounting for water intake of supply chain members. The total water intake for ATC Limited (an associate Company), HDC Hyderabad and RCTI Bhopal (exclusive third party manufacturers for the Cigarettes Business) together was 30,451 kl. Furthermore with an objective of understanding the impacts in the value chain and to draw up an action plan for addressing the key impact areas, in 2010, ITC initiated the life cycle assessment (LCA) for its products and till date 3 LCAs have been completed. In 2014-15, as part of the LCA for one of its products, ITC specifically conducted a water footprint study for a product of the Paperboards and Speciality Papers Business as per the latest Standard (ISO 14046). Details of the results of this study are available for reference in the "Supply Chain" section of this Report. Going forward, ITC intends to undertake more LCA studies for evaluating opportunities for improvement in the value chains of its products and services and take necessary corrective actions.

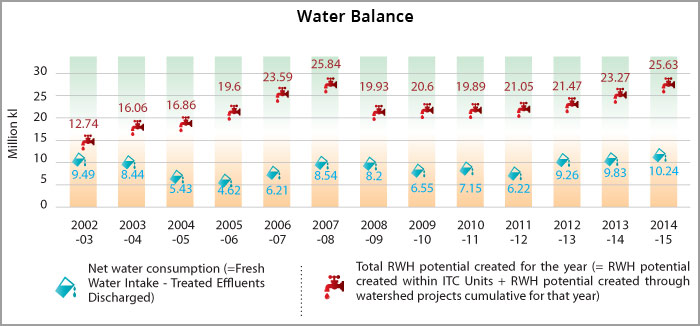

The Company's continued interventions in rainwater harvesting both in the Company premises and socially relevant watershed areas have enlarged ITC's water positive footprint. Details on these interventions are available in the "Social Investments - Mission Sunehra Kal" section of this Report.

The total rainwater harvesting potential created by the Company so far is over two times the net water consumption by ITC's manufacturing operations.

As on March 31, 2015, ITC's Integrated Watershed Development Projects, covering nearly 2,00,186 hectares of land, support the Water Positive status of the Company for the 13th year in a row.

For the watershed structures outside ITC Units, the 'RWH potential' figures from 2008-09 account for silt deposits - the adjustments are based on actual sample measurement & the extent of silt deposit depends on the age & location of a structure.

While continuing its integrated watershed management programme, ITC will be guided by the principles of water stewardship to ensure water security for all stakeholders across all ITC operating Units.