-

Category: Environment

ITC believes its workforce is a key asset contributing to the Company's long term standing as one of India's most admired organisations. The Company believes that a safe and healthy work environment is a basic requirement for ensuring employee well-being and that best practices in occupational health & safety enhance the Company's overall performance. This helps in attracting and retaining quality talent, and enhances the equity of the Company as a responsible Corporate.

ITC's approach towards best-in-class occupational health and safety standards is articulated in the Board approved EHS Policy that emphasises on continual improvement and is based on an environment, health and safety (EHS) management system developed in accordance with internationally recognised standards, supported by continued investments in state-of-art technology and quality human resources.

As a first step, EHS requirements are integrated at the design stage itself for all new investments in the built environment. The design reviews cover building & structural stability, fire & life safety measures, electrical systems, segregation of man-material movements, work place lighting, ventilation & hygiene requirements, noise & dust controls, water and energy use optimisation, traffic safety, etc. The process of incorporating EHS at the design stage not only helps in eliminating/reducing hazards but also optimises the overall infrastructure as well as operational costs.

As a next step, compliance with EHS standards during the construction phase is ensured by implementing appropriate Project EHS management systems. This includes adequate training of all employees including service providers' employees, enforcement of the use of safe equipment/tools/tackles, development of and adherence to safe work procedures/method statements, observance of good housekeeping & storage practices and usage of personal protective equipment. Pre-commissioning audits of all large projects are carried out by Corporate EHS (CEHS) to ensure that all equipment and systems have been procured and installed in conformance with agreed standards and a formal clearance is required to be provided before the project can be operationalised.

At the operational stage, all ITC factories, hotels, warehouses and offices have established EHS management systems with designated roles and responsibilities and competent resources to comply with Corporate EHS Guidelines. These guidelines also require raising of awareness amongst employees, their families and surrounding communities regarding off-the-job safety aspects such as home safety, safe use of LPG in kitchen, HIV/AIDs, hepatitis, dengue, malaria and road safety. As part of ITC's preventive medical program, various categories of employees based on their age and exposure to occupational hazards, undergo periodic medical check-ups.

Compliance is monitored through internal audits by CEHS across ITC establishments on a periodic basis and forms part of the report back to CMC (monthly) and the Board (quarterly), together with accident statistics, their investigation and subsequent closure. In addition, business units adhere to international standards such as OHSAS 18001 and ISO 14001.

The EHS resources of the Divisions provide the support necessary to ensure proper implementation of the ITC EHS policy, while the Unit Heads and the Divisional Management Committees are responsible and accountable for ensuring compliance. The CEHS function is responsible for reviewing and updating standards and guidelines on EHS policies, for providing guidance and support to all concerned and for monitoring compliance at the corporate level.

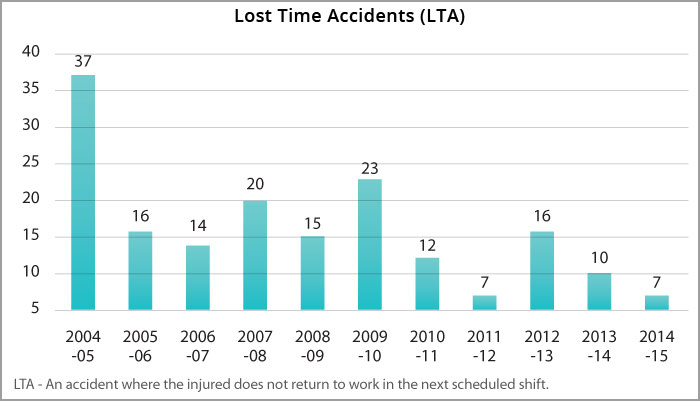

In 2014-15 the number of on-site Lost Time Accidents (LTA) for ITC employees was 7 (against 10 in 2013-14), as depicted below. Since 2004-05, there has been a significant reduction (81%) in LTA although the number of Units and manpower engaged, have gone up manifold. This is attributable to a sound engineering approach and strong management ownership coupled with targeted interventions like behaviour based safety initiatives and tailor made risk assessment programmes at select units. These have contributed towards 2014-15 being a zero fatality year.

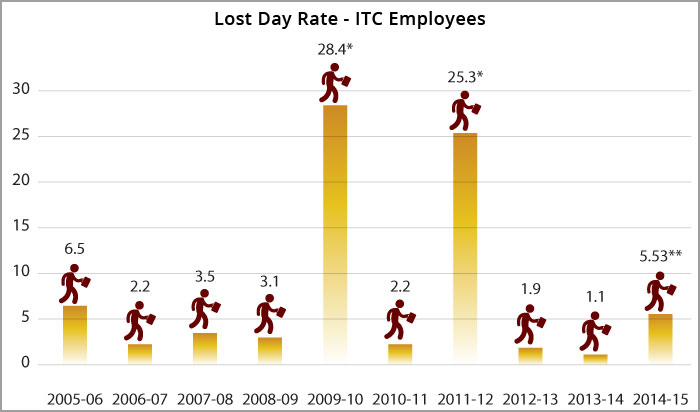

* Increase in lost day rate in 2009-10 & 2011-12 attributable to one fatal accident in each of the years, wherein a loss of 6000 man-days is required to be accounted for as per IS 3786:1983.

** increase in comparison to 2013-14, due to an accident wherein the injured suffered amputation of the right thumb for which a loss of 1800 man-days is required to be accounted for as per IS 3786:1983.

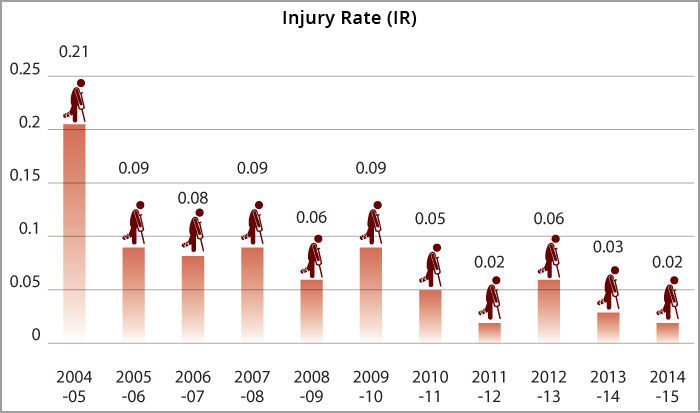

Injury rate, defined as the frequency of injuries in relation to total time worked also shows a significant improvement. Since 2004-05, there has been substantial reduction in the injury rate from 0.21 to 0.02 in 2014-15 (an improvement of 90.5%).

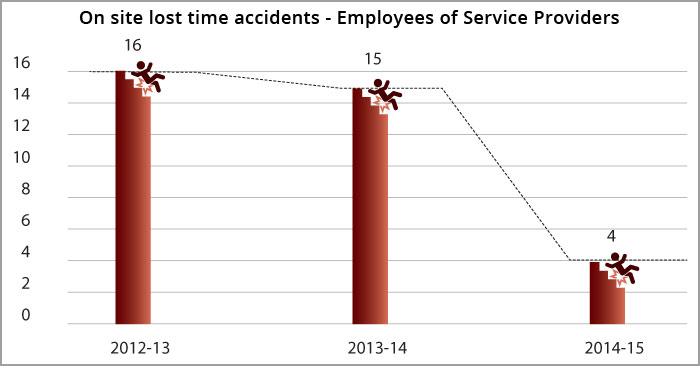

All vendors and service providers within ITC premises are required to follow the same EHS systems applicable to the Company's employees. All employees of service providers also undergo adequate generic as well as job-specific training for safe work procedures and regular briefings and tool box talk have been made an integral part of ITC's safety management system. In addition, service providers' employees are also an integral part of the customised risk assessment training programme, rolled out at several units, to enhance their understanding of risk identification & mitigation.

Since 2012-13, ITC has started reporting on the safety performance of its service providers' employees within ITC premises. The total onsite lost time accidents for service providers' employees for the year was 4 - an improvement of 76%, despite a 48% increase in number of service providers' employees since 2012-13, as depicted below.

Over the years, the number of Units delivering "zero on-site lost time accidents" performance has progressively increased and more importantly, have held on to their performance. Out of the above 45 units, 26 Units have been consistently achieving "zero lost time accidents" status for the last 3 years.

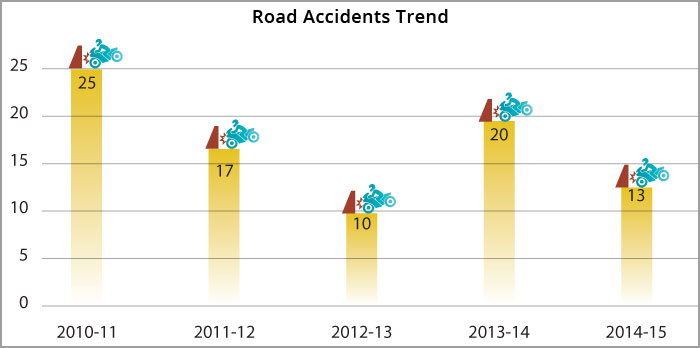

In line with its commitment to ensure the safety of employees, ITC has also initiated adequate measures to ensure safety of its employees working off-site. In ITC, off-site is defined as all places other than the premises where posted, while on official duty, including commuting to and from residence to place of work. Since over the years the majority of the road accidents have involved 2-wheeler riders, a user interactive 2-wheeler rider's safety programme was developed and rolled out in 2011-12, which has now been translated into Hindi for increasing reach. It is likely that this has been a contributory factor in bringing down the number of road accidents to 13 (20 in 2013-14). During 2015-16, ITC plans to translate this programme into Tamil, Telugu, Kannada and Malayalam so as to further extend its reach. This programme is now also being rolled out amongst supply chain stakeholders, by imparting this training to wholesale dealer personnel connected to ITC's Trade Marketing & Distribution vertical.

In addition, ITC is in the process of developing a similar user interactive training module specifically for four-wheeler users. The target population would include managers/employees who use four-wheelers for commuting to/from residence to place of work, as well as official trips. This 4-wheeler defensive driving training module will be rolled out in 2015-16.

A healthy workforce is an important contributor to ITC's competitiveness and sustainability. All Units maintain a conducive work environment meeting Indian/International standards on hygiene, lighting, ventilation and effective controls on noise and dust. Units are provided with occupational health centres with adequate medical staff to monitor occupational health and provide immediate relief, when required. In addition, at least 2% of total employees are professionally trained as first aiders.

Identified medical examinations are conducted at specified intervals for various categories of employees based on age as well as exposure to occupational hazards. Accordingly in 2014-15, 15,535 employees underwent preventive medical examinations and there were no occupation related illnesses identified in any of ITC's business Units.

ITC remains committed to protecting its employees from the threat posed by various serious diseases including HIV/AIDS. During 2014-15, the awareness/ counselling sessions conducted for the employees and communities around ITC's Units covered a total of 20,258 people, out of which 16,386 were employees of the Company, while the remaining were local community members.

Based on the root-cause analysis of accidents over the years, the approach to safety has been redefined with the focus now on fostering a culture of safety and the use of behavioural architecture techniques. In line with the Company's EHS policy, the approach is to institutionalise safety as a value-led concept with focus on inculcating a sense of ownership at all levels, leading to the creation of a safety culture. Periodic reviews are undertaken to ensure that training and other communications are relevant and take into account the local socio-economic context to ensure the transition from "awareness developed" to "changed behaviour".

While ITC will continue to focus on strengthening the engineering control measures through 'design for safety', pre-commissioning/ operational audits and training interventions, based on the encouraging results achieved, ITC plans to expand the coverage of behavioural based safety and custom-made risk based training programmes to other units. This approach which combines empowerment and ownership with targeted interventions and strict accountability should help ITC in its journey to achieve the "Zero Accidents" goal.